At Pack Expo Chicago, from October 14th to October 17th, Marchesini Group will be exhibiting the new MA 400 continuous motion horizontal cartoner, the TURBO-MEK 150 vacuum turbo-emulsifier by DUMEK, the Group’s brand specialized in manufacturing of cosmetic processing machines, and the RE 202 rotary labeler.

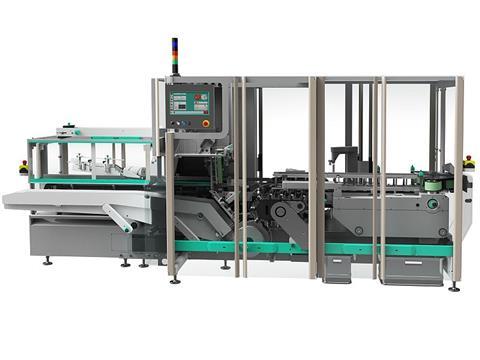

The MA 400 continuous motion cartoner is a completely updated machine with improved ergonomics, reliability and user-friendliness. This machine inherits the best of the BA 400 cartoner, which since the 1980’s has been the global benchmark in efficient reliability and ergonomic design in the pharmaceutical and cosmetic industries.

MA 400 guarantees extremely fast changeover times and low maintenance. It is compact in size - without compromising the machine’s high-speed output and ease of use, thanks to a wide range of control functions that guarantee maximum efficiency. A new operator interface called “Easy Door” has several improvements from both a functional and aesthetic point of view. The new software makes the operating system more powerful and faster. The wider screen is more ergonomic and much more sensitive. MA 400 is a perfect solution for high-speed cartoning of all product types (blisters, bottles and vials, rigid and squeezable tubes, sachets and trays) for the pharmaceutical and cosmetic markets.

The DUMEK TURBO-MEK 150 vacuum turbo-emulsifier is designed to process liquid and cream products for the cosmetic industry, in particular emulsions (cream/milk products), serums, oils and balms, gels and lotions. Special versions of these machines are able to process other products such as make up, suppositories, hair dyes, toothpastes, mud products and shaving creams.

The RE 202 rotary labeler has been developed by Neri, the Group’s branch specialising in the production of labelling machines. RE 202 is a technically advanced and user-friendly machine. It offers customers extraordinary advantages among which are ergonomics and straightforward machine management. Thanks to its accessible work area and container handling control, quick size change-over and extreme accuracy in label application are achieved. The machine’s execution allows for the installation of different track and trace/serialization systems. The design of the RE 202 offers versatility in processing not only bottles made of a variety of materials (glass, plastic and metal) but also of different shapes (cylindrical, truncated cone, oval). It is ideally suited to accommodate containers with shaped profiles and unconventional shapes common to the cosmetic industry. The machine can process up to 200 containers per minute.

At the stand of Marchesini’s co-exhibitor, SEA Vision (Booth No. W-686), - an Italian supplier of vision and inspection systems used in Quality Control and Drug Counterfeiting - will be the BL A415 carton serialization unit, manufactured at Neri’s facility. Thanks to the finest of “Made-in-Italy” engineering, these machines are the standard for whoever needs not only a reliable labeler for pharmaceutical vials and ampoules but also a machine for tracking and serializing them.