In our latest Innovation Spotlight, flexible packaging supplier IMA FLX introduces its new collaboration, bringing together companies from across the chocolate and confectionery sector.

IMA FLX gathered its major strengths to create a cluster of companies with a view to accompanying key players in the chocolate and confectionery sector towards new goals and better business.

The benefits of a single provider

Presenting ourselves as a unique source for this sector, we can count on a solid background and a number of assets. This includes our widespread presence in international markets and a track record of pioneering innovations in the field of packaging across several industries.

Each of the companies in the FLX hub contributes with a specific expertise, experience and knowledge of market trends, all of which is merged synergically into a single-provider concept.

This approach allows us to serve the industry better than if we were acting separately. We can optimise resources, ensure global coverage and local services, share experience and guide our customers towards solutions that will respond closely to tomorrow’s market trends.

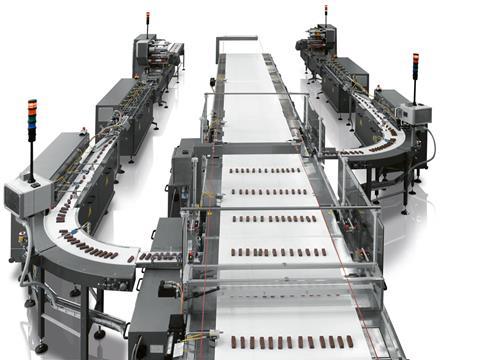

From concept to installation, we supply turnkey lines or single machines on a case-by-case basis.

Our experience at your service

Already part of IMA FLX, our flexible packaging hub, where we develop the most advanced technologies for flexible packaging and research eco-compatible solutions, companies such as IMA ILAPAK, IMA DELTA SYSTEMS (USA), IMA EUROSICMA, and IMA TECMAR (Argentina) all contribute to making a one-stop answer for packaging excellence.

They account for Vertical and Horizontal Form Fill & Seal machines for any type of confectionery product, including lollipops, marshmallows, chocolate tablets, and bars, as well as those listed above.

Packaging varies from Doypacks to block bottom and quad seal bags, and pillow bags. Secondary packaging or end-of-line solutions come in the form of top and side-loading cartoners for display boxes, wrap-around tray packers, multipurpose cartoners, side-loading, top-loading and wrap-around case packers. These are developed by IMA CIEMME.

Testing the future of the industry at IMA OPENLAB

Eager to partner our customers with more than the technological solutions and machines we provide, IMA FLX offers a dedicated research service allowing us to innovate together with companies keen to develop packaging materials of the future.

Focusing on sustainability as a key value, we are constantly testing new flexible packaging materials to ensure they guarantee maximum machinability on our equipment. This is just a part of our consultancy service, whose aim is to devise integrated processing and packaging lines to enhance the quality and efficiency of your production.

We offer the latest-generation solutions to increase your performance, developed as a team composed of IMA FLX, material suppliers, and companies from the confectionery industry.

This content was sponsored by IMA FLX.