With the Sustainability Awards only two weeks away, we asked Joel Wells of Circular about the company’s Cartridge Refill System, said to cut plastic use and emissions by over 80% and a finalist in the Pre-Commercialized Climate category.

You’re a finalist in the Sustainability Awards 2024. Congratulations! To start off, could you summarize your entry?

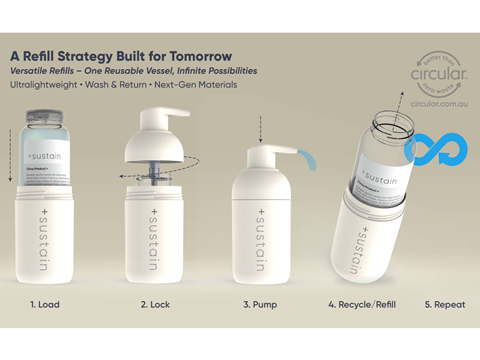

The Circular Cartridge Refill System is engineered to resolve the core issues that cause in-store refills to fail - cost, convenience, and cleanliness. Our patented system features a 3-second refill experience that reduces plastic use and emissions by over 80% and packaging costs by 70%. Offering brands cartridge flexibility between ultralightweight formats designed for maximum material recoverability and durable, reusable, wash-and-return models, Circular’s scalable solution complies with new regulations and enhances brand equity.

Why do you think the judges were impressed with your entry? What is innovative about your project and/or its impact on packaging sustainability?

The judges were likely impressed by the Circular Cartridge Refill System because it delivers a comprehensive, scalable, and low-capex solution to the long-standing challenges of in-store refills - cost, convenience, and cleanliness. Traditional refill systems have struggled to gain mainstream acceptance because they often fail to provide a seamless experience for consumers and retailers alike. Our innovation addresses these issues holistically, offering a practical solution that’s easy to implement at scale without significant capital expenditure.

One of the key differentiators of the Circular Cartridge Refill System is its flexibility. We’ve designed it to accommodate a range of refill cartridges, from ultralightweight formats engineered for the circular economy to durable, reusable wash-and-return options. This versatility enables brands to tailor the system based on geography, infrastructure, and consumer preferences.

Whether it’s a cost-sensitive product or a premium offering, the system can be adapted to meet the desired goals, while also aligning with specific packaging regulations. This level of customization offers brands the opportunity to meet varying consumer demands and regulatory requirements across different markets.

At the heart of the innovation is the 3-second ‘lock ’n load’ refill experience, which makes the process quick, intuitive, and mess-free. Historically, refills have been viewed as inconvenient or unhygienic, deterring widespread adoption. By focusing on consumer convenience, we’ve created a system that eliminates these barriers. The fast, clean refill mechanism enhances the user experience, making it as easy as replacing a traditional product, thereby encouraging consumers to embrace refillable formats.

Beyond convenience, the system also delivers significant environmental and financial benefits. By reducing plastic usage and emissions by over 80%, and cutting packaging costs by up to 70%, brands can achieve both sustainability goals and cost savings.

These financial incentives create a strong business case for companies to transition away from traditional single-use packaging. At the same time, the environmental benefits contribute to corporate social responsibility initiatives, enhancing brand equity and positioning companies as leaders in the circular economy.

The system’s ability to reduce environmental impact while simplifying the consumer experience is key to driving behavioural change. Consumers are increasingly looking for ways to reduce waste, but they need solutions that are both practical and easy to use. Our research shows that the Circular Cartridge Refill System resonates with this demand, with customers often remarking, “why hasn’t this been done before?”

Can you tell us about the ongoing development of your project? How has your innovation been received by the industry, and what are the next steps in commercialization/product development?

We are in the early stages of commercializing the Circular Cartridge Refill System, and the response from the industry has been overwhelmingly positive. Since introducing this innovation, we’ve engaged with key stakeholders across various sectors, from consumer goods brands to packaging manufacturers.

Our immediate focus is on forming strategic partnerships with forward-thinking brands and manufacturers who are eager to adopt and scale this technology. These collaborations are essential to bringing the Circular Cartridge Refill System to market at scale.

One of the key advantages of the Circular Cartridge Refill System is that it leverages existing packaging infrastructure, including tooling, preforms, and caps. This means that brands can transition to this system without the need for substantial upfront investment in new machinery or production lines, making the change not only more sustainable but also highly cost-effective. This ease of integration is particularly attractive to manufacturers, as it minimizes disruption to existing supply chains and operations, while allowing them to capitalize on the growing demand for sustainable packaging.

Our consumer testing indicates that 58% of consumers prefer cartridge-based refills over other options, such as bulk refills (26%) and pouch refills (16%). This strong preference underscores the appeal of cartridge refills, particularly in terms of convenience, ease of use, and hygiene.

The clean, mess-free experience that the Circular system offers addresses many of the pain points consumers have historically associated with refills, such as the inconvenience of bulk refills or the perceived fragility of pouches. This data suggests that cartridge refills are poised to become a popular, if not the dominant, packaging format for everyday household products, from cleaning supplies to personal care items.

Looking ahead, we see the Circular Cartridge Refill System as setting a new industry standard for packaging, particularly in markets where sustainability is increasingly driving purchasing decisions. As more consumers and brands alike prioritize environmentally friendly solutions, we believe this system will become the go-to choice for a wide range of products. We also anticipate that its scalability and flexibility will allow it to meet the diverse needs of global markets, whether brands are looking to reduce plastic use or create closed-loop systems with reusable cartridges.

We are actively seeking partners across various sectors - brands, retailers, and manufacturers - who are interested in joining us on this journey toward a more sustainable future for packaging. If you would like to explore potential collaborations or learn more about how this technology can benefit your business, please reach out to us at joel@circular.com.au.

The winners of the Sustainability Awards 2024 will be announced at the Sustainable Packaging Summit, taking place in Amsterdam on 12-13 November. The Summit mobilizes leaders of the FMCG value chain, policymakers, NGOs, recyclers and investors to collaborate, remove barriers and identify opportunities on the road to sustainable transformation.

To learn more or register, visit: https://www.packagingsummit.earth/2024

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet