DataLase, a provider of photonic printing solutions, has launched a new functional coating for corrugate packaging to further help brands achieve their CSR packaging goals.

The new water based flexo coating, WBF 6101, extends the capability of the DataLase Case Coding solution and enables laser coding and marking of both white and natural kraft (brown) corrugate boxes. This innovative white-to-black laser reactive coating is an alternative solution to traditional labelling of logistical information onto corrugated boxes.

A highly efficient and sustainable way to apply variable information such as shipping information, GS1 Barcodes, batch/date codes and check-weigh information on to corrugate boxes, the new laser printable coating is a viable alternative to high resolution inkjet, waxjet and print and apply labels. Importantly for the environment, it eliminates waste and single use plastics from the supply chain.

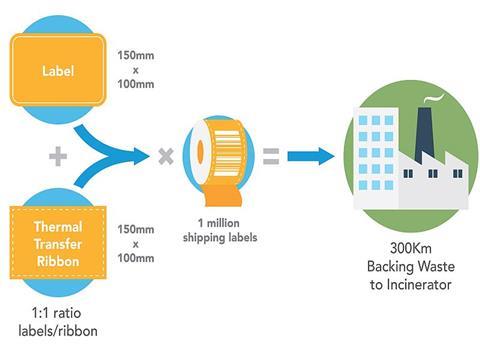

A typical print and apply label produces backing waste with a silicone release coating and thermal transfer ribbon waste which consists of plastics, waxes and resins; both are multi-material and ultimately classed as non-recyclable.Mark Naples, Chief Sales & Marketing Officer at DataLase, said: “Packaging sustainability and single use plastics are front of mind for brands today, with an ever increasing number displaying their commitment through publicising 2025 sustainability targets. We estimate that for every 1 million typical shipping labels used (100x150mm or 4”x6”), approx. 300 kilometres of unnecessary backing waste is produced.

“If we apply this to a typical production environment, it equates to thousands of kilometres of backing and thermal ribbon waste being sent straight to an incinerator every year. The DataLase Case Coding solution creates significant operational savings for manufacturers, as well as contributing to brands packaging sustainability agendas”

DataLase Case Coding aligns with circular economy initiatives, such as the UK Plastics Pact, by removing single use plastics from the production environment. It also brings additional environment advantages, including removal of inks and solvents (VOCs) from the fulfilment area, robust coding avoiding unnecessary waste, high coding throughput and operational reliability. Lasers require minimal preventative maintenance and servicing and no resulting hazardous waste disposal considerations.Where shelf ready packaging (SRP) corrugate design requiring a tear off perforation is involved, DataLase avoids the sticky shipping label getting in the way of the box opening. This results in ease of opening, no damage to the pack when accessed and removes the unsightly on-shelf box appearance so often seen in retailers today.

Finally, the new coating creates high contrast, high quality, durable codes that do not smudge or rub off resulting in less product recalls and penalties from retailers for rework.

Naples concluded: “As we move in 2019 it is clear that we need to think differently about sustainable packaging design. DataLase has invested in unique laser coding and marking solutions that deliver for the whole supply chain, printer, converter, packer and brand owner. Our latest coating launch targeted at supporting brands in moving from white to natural corrugate kraft ensures we can meet the needs of the high growth e-commerce and complex retail sectors with ease.”