In anticipation of the upcoming webinar hosted by Packaging Europe and Markem-Imaje, Tim Sykes discovers why now is the time to discuss GS1-128 barcodes with Derek Dorsey, manager of strategic accounts.

TS: What are GS1-128 barcodes and why is now an important time to talk about them?

DD: GS1-128 barcodes are put onto cases and packs. They encode more data (e.g. batch numbers and locations) than the traditionally used ITF-14s, which only contain Global Trade Identification Numbers (GTINs).

With traceability, pallet splitting and automation increasingly important in today’s digital age, the extra detail provided by GS1-128s is critical to optimising stock management and expediting recalls.

TS: What sorts of challenges can companies face when transitioning to GS1-128?

DD: Picking the right printing solution can be tricky as the quality and placement requirements for this barcode are significantly more stringent than those for ITF-14s. Without the right advice and experience, the transition can be frustrating and inefficient.

TS: Can you give an example of the kinds of trade-offs a business might have to navigate in this process?

DD: Unless manufacturers use a wax ink which dries instantly upon printing the barcode, they may no longer be able print codes directly onto cases. It is difficult to achieve the minimum ANSI grade required for GS1-128s with liquid inks.

For those who ‘print & apply’ labels to cases, unless they choose the right technology, they may need to invest in costly pack-turning devices, reduce production line speeds and/or lengthen existing lines in order to print the labels on two sides as recommended by the standard.

TS: What are the dangers of getting this wrong, and the opportunities from doing it well?

DD: GS1-128 barcodes can encode over 100 pieces of information. This extra case-level visibility makes recalls quicker and more targeted while moving stock through the supply chain more cost-effectively.

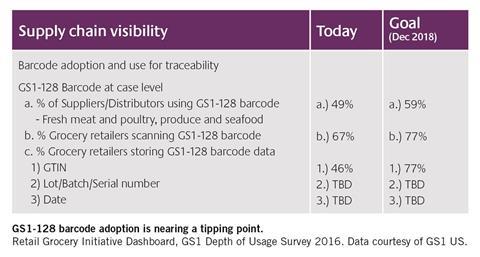

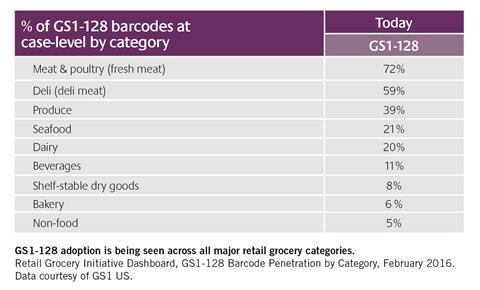

In the US, as of a 2016 Depth of Usage Survey, 67% of grocery retailers were already scanning for GS1-128 barcodes while 49% % of fresh meat, poultry, produce and seafood suppliers reported using GS1-128s. Less perishable items are also being coded with GS1-128s. Not switching could jeopardise trading partnerships and damage brand reputations with laggards not being able to meet retailer and foodservice customer demands to facilitate automation and expedite recalls as quickly as competitors who embrace GS1-128s.

TS: I’m very much looking forward to hosting a webinar on this topic together with you. What can our readers expect if they join us?

DD: They can expect to receive a lot of practical insights and suggestions for how they can transition to GS1-128s relatively painlessly.