Apex International and Troika Systems are bringing together their combined expertise in production processes of anilox roll manufacturing and accurate anilox measurement systems. Labelexpo Europe (25-28 September) in Brussels, Belgium kick started this public collaboration in hall 11 on the Apex stand 11B20 and Troika stand 11A12.

The following interview with Phil Hall, Managing Director of Troika Systems and Toon van Steensel, Plant Manager of Apex Europe outlines the path that led to the partnership and what the future holds.

What led to the decision for Apex and Troika to partner?

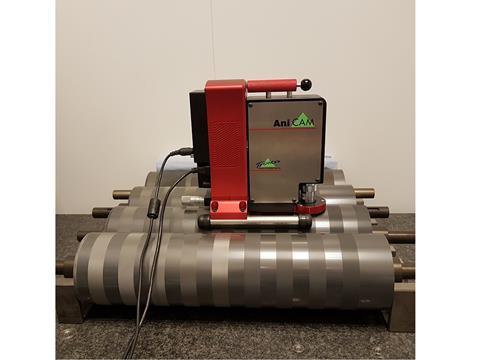

Phil & Toon: Apex and Troika strive for the forefront of product developments which are focused on helping the flexographic industry become more efficient and effective. Over the past decade, a close relationship between the companies has developed where mutual help, advice and continuous improvements has resulted in reputable products (Apex GTT anilox and Troika AniCAM/Anilox QC) and evolvement into market leading positions both companies enjoy today.

The reliability and consistency of measurements from the Troika AniCAM /Anilox QC is an essential part of the print community’s needs, but most importantly for Apex to produce consistent engraving quality from any of their manufacturing sites around the world.

Having proven the standard of volumetric measurement has helped many global printer converters improve their standardization programs, which both Apex and Troika Systems have helped achieve.

It is intended that the mutual respect and cooperation will continue, focusing on continued evolution and developments in response to the ongoing changing technical challenges that will prove to be of further benefit to the flexo industry.

What strengths does Apex bring to the label and flexible packaging industry?

Phil: Apex has certainly assisted all three prime sectors of the industry (label, wide web and corrugated) progress with enhanced print quality, improved production efficiencies and reduced waste by developing anilox technology from the original hexagonal cell structures to modern day engraving structures which meets the needs of the global industry much better.

Investing in the latest engraving techniques and measurement methods has enabled Apex to produce reliable and consistent aniloxes, making it an industry-leading anilox manufacturer it is today.

And what advantages does Troika offer?

Toon: In this industry, you need partners to evolve and innovate: that is what the industry expects from leading suppliers. Troika is a reliable company that continually introduces new innovations and improvements, mirroring the philosophy of Apex to be leading and not following.

Troika offers reliable measurement devices which are extremely important for companies that want to implement standardization and improve the control of their print process with respect to anilox and ink transfer. Especially in the case of fixed palette printing (4C or 7C), this is of the utmost importance. The strength of Troika is they search for a collaboration when they develop new products.

Does Apex currently use Troika measurement tools for the anilox rolls they manufacture?

Toon: Of course! We evaluate all measuring devices on a regular basis that are available in the industry. It does remain an issue, though, to show that Apex and Troika will always measure 100% an equal volume. Therefore, printers need gauge equipment in the form of a gauge anilox roll. On this banded roll, the measuring device will be adjusted and this process will stay necessary for Apex to guarantee to customers worldwide that all rolls coming from each Apex production facility have the exact same volumes.

What is your impression of Apex anilox engravings when it comes to consistency?

Phil: In late 2015, I visited a label printer to check the consistency of the 48 GTT anilox rolls they had purchased from Apex approximately six months earlier. The anilox rolls were in constant use and deep cleaned on a regular basis.

The rolls were measured for differences in volume both laterally and for differences between the individual aniloxes. The maximum variation both laterally and between all the anilox rolls was a remarkable 0.1 cm3/m2, which is the tolerance of the AniCAM with Anilox QC application. This is an indication of the consistency of quality Apex can achieve in production.

How will the partnership be promoted in the future?

Phil: Many print groups globally are looking to standardize their production between plants. Apex has evolved the GTT to a point where it is used by many print groups, with a significant number now using the Troika AniCAM with Anilox QC and the Anilox Management System (AMS) for their inventory management. Using the same measurement systems will ensure compatibility and enhance confidence in what the printers measure and what Apex states is the volume engraved.

Toon: I could not have said it better.

More info: