Sustainability Awards 2017 winner: Machinery

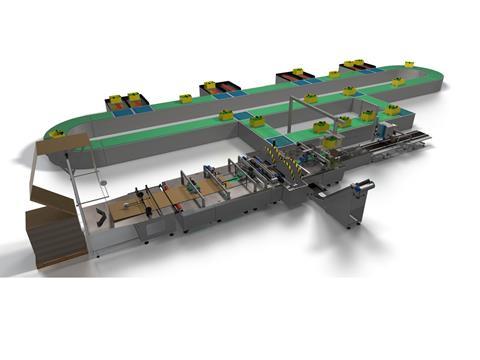

CMC Machinery, CartonPack

CMC Cartonpack, winner in our ‘Sustainable Machinery Innovations’ category, is a fine example of the way smart production technologies can combine serving the customised needs of the multichannel marketplace at optimised environmental efficiency. It was developed by CMC in response to increasing demand from both B2B and B2C e-commerce companies to dynamically pack multiple items of different shapes and sizes in a perfect size box.

It’s worth taking the time to describe how this ingenious system functions. The heart of the system is the Vary-Tote, a CMC designed and patented transport tote featuring two inner adjustable guides used to compact the selected items to the minimum possible volume. The Vary-Totes move on a carousel which brings full totes to the machine induct section and, once empty, conveys the totes to the picking area for refilling. The original Vary-Tote design enables an operator to easily and quickly adapt the inner guides to each individual consignment. A 3D Scanner placed in the CMC VaryTote induct area reads the dimensions of the order set by the adjustable guides. Data about the order dimension is sent to the CMC CartonPack, which creates the exact size flat blank for each consignment. The corrugated board required to create the boxes is fed from a dedicated star-shaped device that smoothly unwinds the fanfold and keeps the cardboard flat to avoid creasing. Flats are dynamically scored and cut. A dedicated Pick and Place mounted in the picking area then places the VaryTote above the flat cut on demand. The bottom of the VaryTote automatically slides and items are accurately placed on the preformed blank while the box panels erects and wraps the items. The on-demand box is now formed, closed and sealed with hot melt glue. The entire process is fully controlled by a dedicated PC Carton controller, which guarantees for 100 per cent data integrity and data exchange with client’s WMS.

Meanwhile, integrated Packvertizing technology combines on demand packaging with 1:1 full colour printing – making it possible to personalise each box with tailored logos, marketing messages and AR. Mounted in the CMC Cartonpack output, it features a module to align the finished boxes. The belt for the transportation of the boxes is spring loaded to compensate for the box shapes if not perfectly squared. A CMC Packjet full colour print head is mounted on a lifting module equipped with a servo motor which optimises the distance between the printer and the carton surface. CMC developed controller can resize every image based on the size of the Cartonpack box and print a 1600x800 DPI image without affecting the machine throughput of up to 700 boxes/hour.

The significance of this innovation reflects the growth of multi-item orders – now up to 60 per cent of online purchases. Collecting, consolidating and packing items of different size and shape it is a challenge and many retailers still rely on manual packing and use packaging materials inefficiently. CMC Cartonpack right size boxes save 30 per cent of the corrugated board, and eliminate the need for the standard void fillers, and in the process reducing the package volume by up to 60 per cent, thus reducing DIM charges. Disruptive technology reducing carbon footprint, reduced cost and better consumer experience make this a worth category winner.