NEW: Banding machine ATS US-3000

Banding has become an increasingly popular packaging solution, from Mondi and ATS-Tanner’s previous work to wrap drinks, fruits, vegetables, and e-commerce deliveries in a single material strip; to Aldi’s trial of a paper band for its bananas. But why should manufacturers choose this solution, and how does it benefit consumers? Urs Fischer, head of Business Unit Sales International at ATS-Tanner, tells us what we might gain by banding – and why we should do it using the company’s machinery.

Let’s start with the basics. What materials are typically used in banding applications?

The range is very wide and varies depending on the product, application, and requirements.

We have paper and monofilm bands from 15 to 100 mm in width in various strengths. The bands have different characteristics in terms of tear resistance, moisture resistance, printability, transparency, and stretchability, for example. We have numerous different qualities for both paper and film – made from virgin raw material or post-consumer recycled material, depending on your wishes and requirements.

We have noticed that our customers are increasingly looking for solutions using paper and want to avoid plastic where it makes sense and is possible. Our in-house development “TruePaper” – a paper band that can be sealed using ultrasonic welding technology but does not contain a plastic coating – is currently very popular.

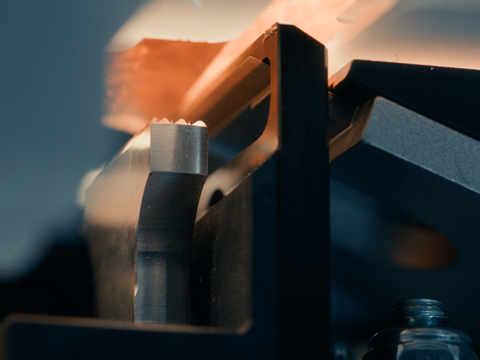

Energy-efficient packaging solution: Patented ultrasonic welding technology

As we all know, the upcoming Packaging and Packaging Waste Regulation is an important consideration in packaging design. How does banding align with sustainability regulation?

The upcoming Packaging and Packaging Waste Regulation has three main targets: reduction of packaging waste, promotion of reuse and recycling, and the use of sustainable materials. Banding fulfills these goals - and goes one step further.

- Banding reduces packaging to the absolute minimum.

- We offer bands made from post-consumer recycled material. Both those made of paper and those made of film. We are constantly expanding our range in this direction.

- Banding makes recycling easy: our bands are made of mono-material and can be opened and separated from the packaged product very easily. Adhesives are not used.

- In addition, the bands can be printed just in time with instructions and labels on how they can be recycled. These instructions increase recycling rates and are already mandatory in some countries.

Could you tell us about the functional benefits of banding solutions, and what they offer to packaging manufacturers?

Banding is extremely versatile and can take on different packaging functions. Here is a selection:

- Branding with banding: embellish products

Bands can be printed on both sides with up to 12 colors and offer plenty of space for information – from recipe ideas and ingredient lists to variable information, such as best-before dates or 1D or 2D codes.

- Adhesive-free labelling

Banding machines with integrated printers band and label in a single step, eliminating the need for additional labelling.

- Closing and sealing of packaging

Whether it is heavy shipping cartons, shoe boxes, meal trays for take-out meals, or cardboard trays for fruits and vegetables, paper or film banding closes packaging securely, gently, and in a customer-friendly manner.

- Bundling with a minimum of packaging

Banding combines smaller consignments or items into larger units to optimize transport and storage processes. Optional just-in-time codes printed on the bands enable goods to be recorded and tracked quickly.

- Multipacks and promotional packaging

A band is frustration-free packaging. The infinitely variable sealing force of ATS ultrasonic sealing technology ensures the right mix of security and ease of opening. Consumers benefit from the simplest possible product handling: there is no need to laboriously cut open films, simply tear them open.

How about consumers? How will their experience with a banded product differ from other kinds of packaging?

As mentioned above, bands are extremely customer-friendly and frustration-free packaging: they are very easy to open by hand (paper bands at any point, film bands when sealing), produce extremely little waste, and can be disposed of correctly and returned to the recycling system with ease.

Tell us more about ATS-Tanner’s US-3000 banding machine. How does it compare to other solutions on the market?

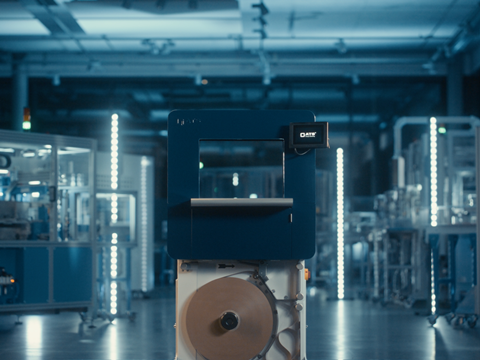

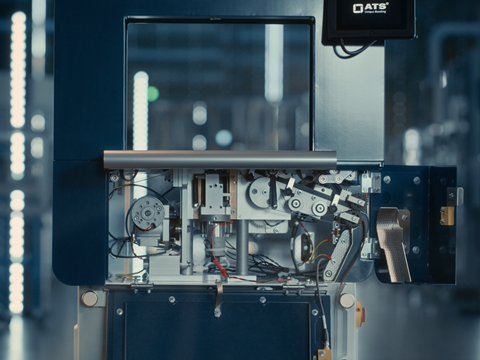

The US-3000 is the successor to the world’s best-selling banding machine and combines the best of more than 30 years of mechanical engineering experience with state-of-the-art technology. We are proud to say that the US-3000 is the most reliable, user-friendly, and sophisticated standalone banding machine we have ever built.

The banding machine with ultrasonic welding technology is the perfect combination of design and function: it is made exclusively of high-quality materials and components. The functionally well-thought-out and timeless design ensures that it is a pleasure to operate and makes it a powerful, sophisticated, and elegant machine with a high recognition value.

A positive user experience increases productivity by avoiding operator errors, reduces training costs, and ensures motivated employees. That’s why we’ve invested heavily in design, from the self-explanatory user interface to the height-adjustable table and effortless band change.

Also important: service and maintenance have never been more efficient. All components are conveniently accessible. The clear separation of mechanics and electronics ensures ideal order, structure, and overview. Error diagnoses and information for rectification are provided via the HMI.

The best thing to do is to visit us at Fachpack in Nuremberg, see the machine and try it out. You must experience it.

The second-best thing is to look at the numerous benefits and impressive videos on our website at ATS US-3000 Banding Machine - Enhance Your Packaging Efficiency (ats-tanner.com).

Service and maintenance have never been more efficient

Why should prospective customers pick ATS-Tanner for their banding requirements?

Here are seven main reasons why a prospective customer should pick ATS-Tanner as their partner:

1. ATS banding machines achieve the highest cycle rates on the market. A critical factor for high productivity and efficient operations.

2. The powerful ATS banding machines achieve the highest band tension on the market. A critical advantage when banding heavy products.

3. Our patented ultrasonic sealing technology: Banding machines with ultrasonic sealing technology are the most powerful, reliable, and energy-efficient packaging machines on the market.

4. We have a wide range of innovative, eco-friendly banding materials. It is as diverse as the applications for which banding is used. We know the characteristics of each of our products down to the last detail.

5. We are there for our customers around the world in the event of a malfunction, with a service or maintenance contract tailored to your individual needs.

6. We are passionate mechanical engineers and software developers. We have a lot of experience in solving challenges, automation, and seamless integration into processes.

7. Designed and built in Switzerland: Our banding machines are built to high quality and safety standards. They are subjected to rigorous endurance testing before delivery.

Our US-3000 is the new standard banding machine for industrial environments; see https://www.ats-tanner.com/en/lp/the-new-ats-banding-machine.

We and our brand-new US-3000 are at Fachpack – Hall 7A, Booth 414.

To learn more about banding and what ATS-Tanner can offer, click here.

ATS-Tanner’s previous In Conversation With… feature is also available to view here.