Aseptic cartons have enjoyed growing popularity thanks to benefits such as enabling ambient distribution, offering product protection, cube efficiency and convenience.

According to market research from Data Bridge, the global aseptic packaging market amounted to USD 31.6 billion in 2017, growing at a CAGR of 9.9 per cent during the forecast period of 2018 to 2025. Elisabeth Skoda talks to industry giants Tetra Pak, SIG and Elopak about aseptic cartons compare with other pack forms and explores recent innovations in the areas of efficiency and sustainability.

Aseptic cartons enable wide distribution of food products at ambient temperatures while maintaining the nutritional quality and safety of the food within markets where chilled food distribution is not well established.

“A beverage product is protected,” says Elopak’s environment specialist manager Elisa Gasperini, “by packaging which provides barriers to micro-organisms and physical and chemical factors including light and oxygen which can cause damage to its quality such as loss of flavour, nutritional value and freshness.”

This means consumers can store the products for longer without refrigeration and with no preservatives. “For food and beverage manufacturers efficiency, cost-effectiveness and sustainability aspects are also decisive factors for choosing aseptic cartons,” comments Norman Gierow, head of marketing in Europe at SIG, who see them as the perfect package. “They are among the most environmentally friendly packaging solutions. Their main material is paper board made from renewable wood and their lightweight, space-saving design is efficient to make, fill and transport. Carton packs are eye-catching, unbreakable, easy to open and equipped with the all-important convenience factor.”

The consumer is king

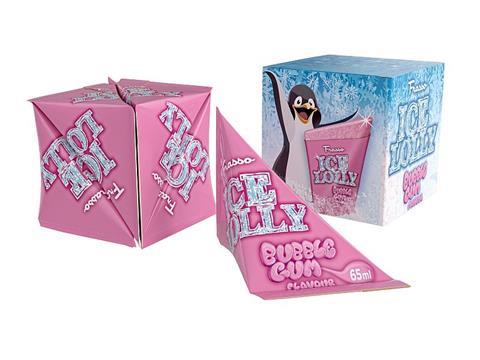

Many trends impacting on developments in cartons are consumer-driven, as Tetra Pak’s product director Hermant Krashak observes: “We saw two clear trends in the 2018 Tetra Pak Index: a strong desire for convenience and growing sustainability concerns. In terms of convenience, consumers have shown more appreciation for space-efficient packaging. Aseptic carton packaging is designed to be space-efficient but is also beneficial to food producers as it maximises space during distribution. Consumers are increasingly aware of their environmental impact. The Tetra Classic Aseptic 65ml Cube, responding to this, is designed to enhance distribution efficiency. The dimensions of the package have been designed to allow every six packages to form a cube, hence optimising the use of space in distribution and storage, bringing significant improvement in cost efficiencies and the environmental footprint.”

Mr Gierow echoes the importance of sustainability to consumers and highlights consumer mobility as an important driver. “On a global scale, with rising middle classes, people are no longer driven purely by price but by the promise of better sustainability, health, quality and experience. At the same time, the demand for nutritious and affordable food products is growing. Due to shifting demographics and rapid urbanisation, consumers are living more on-the-go lifestyles, which is impacting the way they consume products. They are seeking convenient packaging solutions that are not only easy to use but enhance their experience and reduce their impact on the environment.”

But consumers want convenience as well as sustainability, and recent innovation has been directed at conveniently complementing the patterns of daily life. Tetra Pak’s DreamCap is a good example – the ‘Edge’ refers to the slanting top of the package, which is designed to improve the liquid flow and provide space for a large opening on the small, on-the-go carton formats.

In addition, consumers like information to be easily accessible. In this respect, Mr Krashak believes that smart packs offer rich potential for a consumer experience. “Every pack sold can carry a unique digital identifier, creating the opportunity for direct one-to-one conversations with consumers,” he remarks. “Our research has also shown that consumers are increasingly looking for novelty and fun in their products, as they use consumption as a means of expressing themselves. The Tetra Pak Index 2018 reveals that brands are expected to appeal to consumers on an ever more personal level, with customisation of products and personalisation set to be key differentiators moving forwards.”

Beverage carton 4.0

Consumers are also increasingly vociferous in their desire for assurance about product security – and the added value of traceability is hastening investment in digital manufacturing technologies with wider benefits at the bottom line. Automation is now at full swing in the industry, and Tetra Pak for one is introducing its ‘factory of the future’ human-AI collaboration vision at the Hannover Messe as we go to press.

“As filling plants and factories operate on an unprecedented scale, production lines need to be more flexible, individualised and agile to handle periods of higher outputs and faster product changes,” Mr Gierow comments. “This can only be achieved by securing greater asset optimisation, configuring the optimal long-term infrastructure that can flexibly handle any operational demand. This is only possible with an optimal production setup, perfectly harmonised processes and a fully automated integration – from raw material intake to shipping finished goods. It’s crucial to get the most out of filling units, reduce the risk of downtime and to connect, automate and monitor lines, while driving down costs.”

Reducing the environmental impact

All three manufacturers agree that aseptic carton packaging plays an important role in reducing food waste and minimising the carbon footprint.

Ms Gasperini points out: “Aseptic packaging does not require refrigeration and thus saves energy in the storage of the product. Food waste is a primary concern and aseptic packaging helps to reduce food waste by allowing for extended shelf life, whilst keeping the product fresh and maintaining nutritional value. Beverage cartons are lightweight and easy to transport.”

“Complemented by resealable closures, these packages can further help extend the life of products and reduce waste in the home,” Mr Krashak adds.

Mr Gierow highlights independent life cycle assessments that he claims have shown a better environmental performance by aseptic cartons than glass, HDPE or PET bottles, pouches and cans.

“Aseptic cartons are made from 70-80 per cent liquid packaging board, which comes from wood. This means the LPB in our packs has a very low carbon footprint compared with other packaging materials. Secondly, the efficient shape of aseptic cartons means that after filling they can be stacked together closely with minimal wasted space. A trailer of filled carton packs carries around 95 per cent content with just five per cent of the space taken by the packaging. This makes cartons more efficient to transport than round shapes, such as bottles, resulting in fewer trucks on the roads, less fuel used and less space needed to store the products.”

Overcoming challenges with innovations

With consumers increasingly conscious of the problems associated with packaging waste, circularity has emerged as a major focus for innovation.

Elopak’s director of strategic marketing & product management, Paul Sweeting highlights the Pure-Pak® Aseptic system for UHT products and the EPS120A filling machine from Elopak: “In August 2017 Elopak launched Pure-Pak® cartons with Natural Brown Board, giving a natural feel and look to the carton, whilst removing layers and improving environmental impact. Consumers instinctively choose this as a more sustainable product and some customers have converted from plastic bottles to using this package. The Pure-Pak® gable top carton is now being used in long life milk and plant-based beverage applications in addition to juices and still drinks. The Pure-Pak® carton offers a premium image and the best pouring characteristics.”

Mr Gierow is keen to point out the challenge to make packs even more sustainable, and efforts are being made to also source the other key materials – aluminium and polymers – responsibly.

“Certifications for the polymers and aluminium materials are not as well established as FSCTM but we’ve been exploring suitable options.”

He highlights that the polymers used for laminating the paperboard and making the spout for SIGNATURE PACK – which he claims is the world’s first aseptic carton pack with a clear link to 100 per cent plant-based renewable materials – originate from renewable European wood sources and are certified according to ISCC PLUS (International Sustainability & Carbon Certification) or CMS 71 (TÜV SÜD certification standard) respectively, via a mass balance system.

“We’re also at the forefront of efforts to drive a new certification programme from the Aluminium Stewardship Initiative (ASI) – the ASI Performance Standard Material Stewardship Principle. SIG is the first in the industry to achieve certification to this programme, which is designed to recognise and collaboratively foster responsible production, sourcing and stewardship of aluminium.”

All three companies emphasise that their cartons are fully recyclable, as well as sourced from FSCTM certified wood. But how many cartons today actually get recycled? The latest figures indicate that levels across Europe linger at 48 per cent. The technical challenge, of course, is the laminated layers of paper and barrier materials, which can be hard to separate in an economically viable way. In this context, Tetra Pak’s collaboration with Veolia (discussed in our interview with Laurent Auguste in the previous edition of Packaging Europe) will be of critical importance.