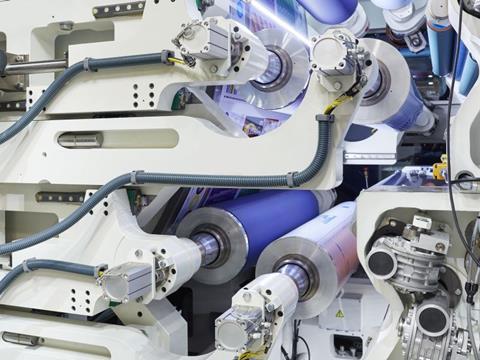

Comexi had launched for the first time ever a central impression offset solution for flexible packaging back in 2012. After seven years of development, the new generation of offset CI8 press has introduced new solutions for colour matching and colour stability, which the company says saves nearly 50% with respect to set up time and 40% regarding material waste.

The new iCIP3 software perfectly matches pre-press colour information with both CTP and press, creating a harmonized colour matching process. Furthermore, the SOP (Standard Operation Procedure) details the set up and usage of both iCIP3 and ink fountain control to reduce the sensitivity of the process operating skills. As a result, the high level of colour management automatization renders a more standardized, simpler, and accurate colour matching process, leading to a fast, efficient, and consistent set up time and waste reduction.

A cost-effective short run solution

As decreasing the average job length is a world-wide trend, the pre-press cost is increasingly becoming more important. For a 10.000 m2 project, the pre-press cost can represent up to 80% of the total printing cost. A complete set of offset plates for less than 50€ exemplifies an astronomical cost reduction: 20 times less than other conventional printing technologies. Furthermore, the extremely fast in-house production of plates allows to be manufactured in under 20 minutes.

Unlike other technologies, the cost of ink per square meter is equivalent to conventional printing methods. A higher cost of EB offset ink per kilogram is compensated by a substantial reduction of the ink deposit per square meter. Additionally, as a result of the highly efficient EB curing process, power consumption is reduced by up to 50% in comparison with other printing solutions. Moreover, the extremely rapid robotized sleeve changeover enables an automatic 8-colour job change in 14 minutes without human intervention. Taking everything into consideration, the Comexi Offset Central Impression press is certainly the ultimate cost-effective solution for short runs.

An environmental solution for flexible packaging

Flexible packaging is at the centre of a necessary debate on waste management and a circular economy. Having been the most efficient and safe food packaging technology, there is important work to be done in regard to appropriately educating the society on waste disposal. On the other hand, once packaging is properly collected, it must be recycled. The reality is that most of today’s flexible packaging is not.

Consequently, recyclability is quickly emerging as the cornerstone of packaging design, steering our industry to reducing the number of end product layers. A key application of the offset CI press is the substitution of reverse printed and laminated structures for frontal printing with an in-line high glossy anti-scratch coating. This is the most environmental-friendly and cost-effective way of transform flexible packaging into a recyclable solution, as demonstrated in the exclusion of PET from many of the triplex or simple laminates currently available. Visit Comexi in Hall 4 Stand B33 to see some examples.

The Offset EB inks and coatings are 100% solvent free, assisting converters and brand owners to significantly reduce their carbon footprint, as well as avoid solvent retention and the risk of explosion.