Siegwerk has launched its first full UV flexo deinking system for the European market, CIRKIT CLEARPRIME UV E02, designed to be a ‘validated solution’ for safe and economic deinking of UV-printed self-adhesive labels (PSL) and improve a pack’s recyclability.

The new primer technology for non-food packaging applications is said to improve the recyclability of labelled plastic packaging and enable the recovery of high-quality recyclates that are suitable for reuse in non-food packaging applications.

Siegwerk says that although UV inks offer some advantageous properties for printing labels, they also pose a challenge for the subsequent recycling. “Depending on the substrate, UV inks are often very difficult to remove and can therefore lead to contaminations of recyclates, which significantly limits their further reuse,” explains Marc Larvor, head of Technology Narrow EMEA at Siegwerk. “As a result, it is not surprising that UV-printed packaging has so far been considered as problematic in terms of a Circular Economy.”

The company hopes to address this challenge with its new solution and eliminate the need for prior label removal if the used plastics are compatible. It also states that the combined mechanical recycling of labels and plastic packaging should help to increase recycling rates and save time and costs.

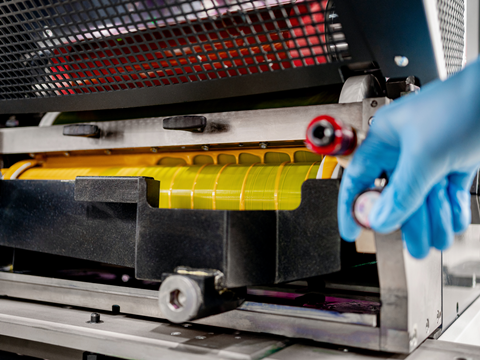

The deinking primer has apparently proven its effectiveness in a first field test with European label supplier Masterpress, where research and development experts used uncoated transparent or white pressure sensitive labels (PSL) made of PE85 and applied Siegwerk’s CIRKIT CLEARPRIME UV E02, followed by bleeding resistant UV flexo inks and an UV flexo OPV.

Siegwerk states that the primer created a ‘perfect adhesion’ between substrate and inks and later enabled full ink and varnish removal of the printed polyethylene (PE) film at standard deinking conditions, based on the QT 507 washing protocol of the European PET Bottle Platform (EPBP). The primer layer reportedly dissolved residue-free in the hot washing process.

The primer can work with Siegwerk’s Sicura flexo series including the non-low migration Sicura Flex 39-8 or the dual-curing series Sicura Flex Dual Cure. The primer is said to be compliant with different film materials and allow an inline printing of de-inkable materials in a 100% UV-Flexo press setup, aiming to keep the user complexity low.

In April, alongside Windmöller & Hölscher and B&B, Siegwerk applied its CIRKIT functional coatings to the development of a mono-PE bag, aiming to produce a high-barrier, fully recyclable packaging solution for dry pet food. The bag apparently offers the same packaging performance as complex multi-material alternatives, while also claiming to offer full recyclability.

More recently, Videojet announced its 9560 automated labelling system for printing and applying labels to outer cases, boxes and shrink wrap. The system is said to feature increased processing speeds and expanded connectivity options.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet