SEE is implementing new digital die-cutting capabilities for its Sealed Air brand Korrvu retention and suspension packaging, aiming to decrease production lead times and free up storage space at customer facilities.

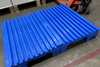

Korrvu packaging surrounds products with a low-slip film to protect them from shock and vibration without sacrificing visibility. To simplify consumer recycling, the packaging itself is kerbside recyclable with the plastic film attached.

With digital die cutting, it is hoped that lead times will be lowered from months down to weeks. Customers can also place smaller minimum order quantities, SEE explains, which negates the need for customers to store excess packaging on-site.

Additionally, digital technology is expected to unlock high-volume and short-run orders for on-demand production – freeing up space in warehouses by letting customers store only the necessary amount of packaging.

Physical tooling is no longer required, and customers can more easily tailor their designs to products, seasons, locations, and customers. The corrugate can be engraved with lasers and cut out to differentiate packaging from that of market competitors.

Digital finishing is also hoped to reduce the carbon footprint of a supply chain by simplifying its operations. Reportedly, Korrvu packaging contains at least 50% recycled content, can be reused, and is recyclable at kerbside.

“Korrvu packaging solutions were traditionally cut with physical dies that were made to order for each customer,” explained Ingo Lublow, EMEA director Protective & Equipment Marketing at SEE. “That process could take months to perfect.

“Our new digital Korrvu capabilities eliminate the need for custom tooling, so our customers can get their designs prototyped, sampled, and into production much more quickly.”

Last March, SEE held its PACK DIGITAL event in Milan. This anticipated the launch of its prismiq portfolio of solutions for design services, digital printing, and connected packaging.

Since then, it has incorporated a minimum of 95% recycled plastic content into its BubbleWrap Brand inflatable air pillows; and it has produced a paper-based bottom web to help food processors and retailers cut down on plastic usage and meet consumer demand for paper-based packaging.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

The way we talk about plastic needs to change – here’s how to get it right

What steps is Apple taking to make its packaging more sustainable?

No comments yet