Aptar CSP Technologies and ProAmpac have combined their respective active material science solution and flexible blown film technology to create a patent-pending, moisture-adsorbing flexible packaging solution – a move expected to protect sensitive medical products and enhance their performance.

Aptar CSP’s Activ-Polymer technology is custom-engineered for product-specific protection in applications such as drugs, diabetes test strips, continuous glucose monitoring devices, probiotics, drug delivery devices, and medical devices and implants. Its capabilities reportedly include scavenging oxygen, odours, and VOCs, releasing aromas or antimicrobials, and preventing the formation of mutagenic N-nitrosamine impurity and drug degradation.

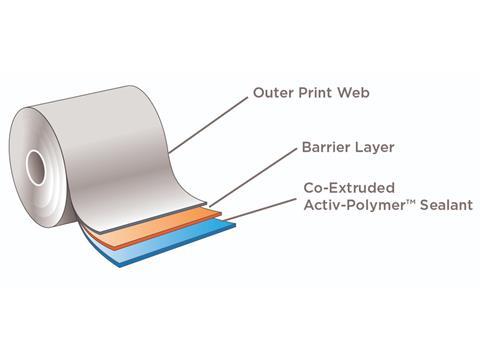

In turn, its 3-Phase Activ-Polymer platform technology is a highly engineered active material science solution designed to protect foods, drug delivery systems, medical devices, probiotics, and sensitive drug products. The moisture-adsorbing Activ-Polymer material is incorporated into a flexible film structure to create the ProActive Intelligence Moisture Protect (MP-100) platform technology.

MP-1000 is designed to adsorb excess moisture inside the package and protect against moisture molecules that would otherwise enter the packaging before an add-on desiccant can be applied. As such, it negates the need for desiccant sachets in moisture protection and intends to lower downtime in the manufacturing process.

Varying moisture capacities are available for customers to customize their microclimate protection requirements. The packaging is available in rollstock or pre-made pouches and claims to offer ‘excellent’ seal characteristics.

It also runs on high-speed form-fill-sealing equipment in a bid to align with existing flexible packaging equipment while maintaining the integrity of the product.

“We are pleased to unveil this new platform of active material science solutions with ProAmpac,” said Badre Hammond, vice president of global commercial operations and general manager APAC for Aptar CSP Technologies. “The goal of this collaboration is to transform the way active packaging is delivered and fulfill unmet needs by providing the market with a fully integrated, flexible, multi-layer film solution, powered by CSP’s proven Activ-Polymer technology.

“We look forward to continuing our collaboration with ProAmpac to leverage the current platform to develop new active materials that address a broad range of product stability challenges.”

“We are excited to launch the Moisture Protect MP-1000 platforms, the newest addition to the ProActive Intelligence product line,” added Hesam Tabatabaei, senior vice president of global product development and innovation for ProAmpac. “This innovative product has a high moisture-adsorbing capacity and is set to revolutionize moisture protection in flexible packaging.

“Our extensive material science work and exclusive collaboration with Aptar CSP Technologies has enabled us to bring the latest active packaging products to the market.”

Back in 2020, Aptar CSP Technologies enhanced its Activ-Film product with combined oxygen scavenging and moisture adsorption capability to produce a fully integrated, moisture- and oxidation-sensitive solution for drug products. It was set to enhance the protection of its various packaging configurations, including its Activ-Blister, for a range of products – including oral solid dose medications and probiotics.

More recently, StePacPPC has sought to protect a range of whole, sliced, and fresh mushroom products with improvements to its modified atmosphere packaging. The tailored packaging is expected to extend the products’ short shelf life to cut down on food waste and costs.

Meanwhile, ProAmpac is bringing a 90% fibre-based, high-barrier thermoforming solution to the European market; the solution aims to improve the recyclability, efficiency, and consumer appeal of food packaging.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

The way we talk about plastic needs to change – here’s how to get it right

What steps is Apple taking to make its packaging more sustainable?

No comments yet