Fachpack is back at the Messezentrum Nuremberg from 23rd – 25th September. Packaging Europe will report live from the show floor, giving you a real-time rundown of the event’s highlights.

Watch this space for the latest news and commentary, exclusive interviews, and all the things you need to see at this year’s trade show.

What to expect from Fachpack 2025

The focus of this year’s Fachpack conference, “Transition in Packaging” will be reflected across 11 exhibition halls and 1400 exhibitors in Nuremburg from the 23rd to the 25th of September 2025.

The conference aims to bring Europe together. “Fifty-four percent of exhibitors come from the strong German-speaking economic area, while the rest hail from all over Europe,” says the event’s director, Phuong Anh Do.

Around 60% of exhibitors work in the packaging segment, i.e. packaging, packaging materials, and accessories. Some 40% cover the packaging technology segment, i.e. packaging machines, marking and labelling technology, and automation. The packaging printing and finishing, and internal logistics segments are also represented at Fachpack.

In terms of macro-trends that relate to the overall theme of this year’s event, the organizers of Fachpack highlight sputtering consumption slowing down demand, increasing costs for raw materials that are driving packaging prices up, and unfavourable competitive conditions in the machine manufacturing sector that are impeding investment.

Three forums across PACKBOX (Hall 4), INNOVATIONBOX (Hall 7) and SOLPACK 6.0 (Hall 3) will address these issues, as well as the challenges of the PPWR regulations, climate change, the circular economy, digitalisation and AI, or alternative packaging solutions and new or alternative fibre raw materials.

Before all of this, the day before the start of Fachpack, Futury GmbH joins forces with EIT Food to gather leading players from the European packaging start-up scene at the FuturePack Summit.

On the first day of the fair the networking event WOMEN4PACKAGING offers female players from the sector a unique opportunity to network, inspire one another, and discuss the latest topics and trends in the packaging industry. Steffanie Rainer, CEO and founder of reo, and Simone Mosca, Managing Director of Mosca GmbH, will be presenting.

Also on the first day of the fair, the 37 winners of The German Packaging Awards will be announced at 16.30 in the Munich Room in NCC Mitte

The Student Day on the third day of the fair brings companies and young packaging talent together. At the invitation of FACHPACK and the German Packaging Institute (dvi), a large number of students from the German-speaking regions will take part in workshops with professionals from packaging firms and branded companies.

The “Converting meets Packaging” pavilion, featuring seven exhibitors, will make its debut in Hall 7. The aim is to facilitate communication between converters, packaging machine manufacturers and packaging producers and identify potential for improved collaboration.

The “Alternative Packaging Solutions” pavilion will make its second appearance at Fachpack 2025. It will showcase examples of alternatives to commonly used materials and provide insights into what might be possible in the future.

Visitors can also look forward to the “Young Innovators” pavilion for innovative young companies that is subsidised by the German Federal Ministry for Economic Affairs and Energy (BMWE).

In addition, the “Newcomer Pavilion” gives FACHPACK newbies or international newcomers to the industry a platform for presenting their companies and innovative products or services to a professional audience.

And naturally, FACHPACK 2025 would not be complete without the popular “Labels & More” pavilion in Hall 7.

More information on all the above can be found on the official Fachpack website.

Things to see

At Sappi’s stand, we were introduced to its GUARD range of barrier papers; these include the lovingly nicknamed ‘power couple’, Guard Pro OHS in Gloss and Natural variants, and the new Guard Pro OMH.

Available with or without heat-sealability, the lineup offers resistance to oil, grease, and water vapour – and has already been adopted by big brand owners.

Our conversation with Filip van Ranst, sales director for Flexible Packaging, gave us insight into the company’s ethos. Total cost of ownership remains an important consideration, especially as soaring costs in the European industry threaten to limit smaller players to conventional plastic formats.

While van Ranst acknowledged that paper packaging is not a realistic or functional solution for every product, Sappi’s goal is not to push every customer into radical redesigns. In his mind, successfully converting 20-30% of the industry’s output to paper is a good start for the planet – and while it may take time, the sustainability revolution for packaging is incoming.

Fibre-based packaging solutions with Matrix Pack

At Fachpack 2025, Dionysis Valentis talks us through Matrix Pack’s range of fibre-based solutions, featuring ready meal trays and bowls for the food industry as well as new product lines for butter and margerine and cutlery solutions.

Material agnostic innovation with Mondi

As Fachpack draws to a close, Paulus Goess discusses Mondi’s full range of packaging solutions, including kraft paper, paper bags, e-commerce solutions, as well as its box business and flexible packaging.

At Hall 4, Stand 322, Jörg Sabo, Greiner’s global marketing & innovation director, showed us a range of solutions – demonstrating the variety of his company’s output.

First-off, we took a look at some pre-commercialised solutions – such as CUBO; a logistics optimised design that has been developed with stacking and space-saving in mind. The Click In and Click On seal caps were also presented at this point, with user access and accessibility in mind.

Next came a solution Packaging Europe is very familiar with: K3 r100. This pack has an outer cardboard layer for decoration and an inner plastic layer for functionality, allowing the user to easily separate the two after they have consumed the product within, with the aim of making the recycling process more efficient.

Reuse and refill were also high on the agenda for Greiner, and we were interested to learn more about the company’s efforts in this field – from small office-scale operations to much larger projects. We will hopefully have more information on the latter to share with you soon!

At the end of our visit, the Packaging Europe team had a go on Greiner’s interactive spin-the-wheel-quiz – a great way to round off a fascinating half-hour.

At the UFlex booth, Apoorvshree Chaturvedi and his colleagues highlighted that UFlex specializes not only in film, but packaging as a whole – and while it is the largest multinational flexible packaging company in India, it considers itself a European company first and foremost.

“We are local, we are reliable,” Chaturvedi told us. “We are not putting the customer’s budget at risk by forcing them to get the goods transported from far-off shores.”

This approach is especially beneficial in light of increasing expenses across the continent, the environmental concerns associated with importing raw materials, and concerns surrounding the future of the EU Single Market. Indeed, UFlex emphasized that it generates its own PCR chips at its acrylic coating facility in Egypt.

It went on to foreground its efforts to buy, crush, and chemically recycle plastic bottles into products like core plugs and garden grates, but also to locally source and recycle multi-material flexible polyolefins into new packaging films.

Among its product highlights was B-UUB-M, a heat-sealable, recyclable, and high-barrier metallized BOPP film already used by major coffee brands. It is believed to improve the shelf life of crisps and snacks by 50% while avoiding carcinogenic additives and processing at high speeds.

To learn more about UFlex’s work, visit Hall 6, Booth 146.

On the final day of Fachpack 2025, we spent an hour at Coveris’ stand in Hall 4 to learn about how the company is looking to put its “No Waste” vision into practice.

To kick things off, we discussed sleeve innovations with product manager Thorsten Umek. He demonstrated the SleeveFlexR stretch solution with a range of different PCR content options – from 35% all the way up to 75%.

The recycled materials themselves are produced as a result of Coveris’ ReCover-Deinking recycling plant – which seeks to enable a full recycling loop. We’ll have more information on this initiative in the future – stay tuned!

Next, Bernhard Mumelter talked us through the company’s partnership with Nextek, a previous overall winner of Packaging Europe’s Sustainability Awards.

The two companies recently announced a partnership aiming to convert post-consumer polyolefin packaging waste into food-grade recycled resins and films using Nextek’s COtooCLEAN process, and we eagerly await news on the progress of this landmark project.

Finally, Melinda Bonamour, market development director for paper, showed us that Coveris is also innovating in the paper-based packaging space with products like the MonoflexFibre Pure Max – which offers offers pre-made bags and form-fill-seal solutions made of paper, aiming to help customers transition into high-barrier yet recyclable packaging solutions in compliance with EU regulation.

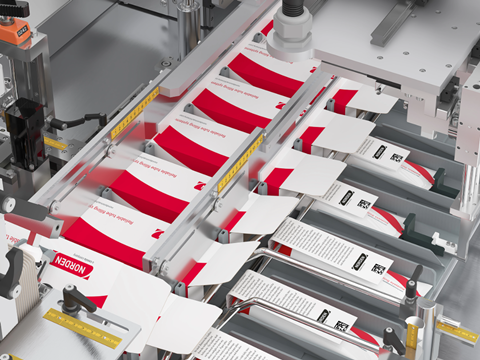

At Hall 3C, Booth 230, Magnus Nilsson, Area Sales Manager at Norden, demonstrated his company’s brand-new NC100 Cartoner - which can produce up to 100 cartons per minute.

The new machine can handle multiple different kinds of closure options and advanced marking systems, with the aim of enabling full traceability.

The NC100 was demonstrated to Packaging Europe in conjunction with Norden’s 902 Tube Filler, which is also capable of handling 100 tubes per minute.

Norden stressed to us the importance to its clients of adaptability and flexibility, and both machines can create products in various sizes and styles. As Nilsson said to us: ”You know what you are producing today, you have no clue what you are producing tomorrow.” Wise words indeed.

Wipak showcases digital watermarking on demonstration belt

Florian Constabel, head of Wipak N.E.X.T. & Digimarc, takes us on a walking tour of the company’s digital watermark demonstration belt – showcasing how customers can adapt their packaging for the age of digitalization.

Visit Wipak at Hall 4, Booth 4-312 to see for yourself!

Banding machinery innovation with ATS Tanner

Live on the show floor, Urs Fischer presents ATS Tanner’s latest innovations in banding technology, with a focus on the new US-2500 banding machine line, which allows automated banding, printed banding, banding with big arches and much more.

Reflections on the first two days of Fachpack 2025

Over the past few days, the two members of Packaging Europe’s content team who are on the ground at Fachpack 2025 have walked close to 80 thousand steps, shaken hundreds of hands, and witnessed countless examples of true packaging innovation.

This year’s edition of the show has taken place across 11 halls and roughly 1,500 stands, most of which we’ve seen at some point during our time here. We write about packaging innovation every day, but seeing these innovations in action, and speaking to the people behind them, has been truly inspiring.

It’s also been inspiring to meet with friends of Packaging Europe who we talk to frequently but don’t often get the chance to see in person. Winnie Mühling, director of marketing and communication at ProCarton, is one such person.

At the ProCarton stand (hall 3A, stand 130), Winnie, with his trademark passion for and knowledge of the industry, presented the winners of the 2025 ProCarton Awards.

Of particular interest were the winner of ‘Carton of the Year’ award (Metsä Board and Van Genechten Packaging’s Lumene 24 Nordic Beauty Secrets pack) and the winner of the ‘General’ award (a collaboration between Cosack GmbH & Co., KG Druck + Verpackung, and Smurfit Westrock).

Beyond being functionally innovative, Winnie noted that these winners are prime examples of “packaging as art” – we heartily agree.

Low emission steel drum innovation with Greif

Kicking off our video coverage, Sandor Orban discusses Greif’s launch of the new EcoBalance™ low carbon emission steel drum, which has been certified through ArcelorMittal XCarb® and achieves ~60% cradle-to-gate CO₂ footprint reduction.

Visit the company in hall 5 at stand 116.

Masterpress will showcase paper-based and single-layer PE pouches, alongside shrink sleeve products, envelopes, and paper bags – all designed for recyclability.

In the wake of the German Ink Ordinance and Packaging and Packaging Waste Regulation, Masterpress aims to meet brand owner demand for cost-effective and recyclable packaging.

“At this year’s FACHPACK we want to reinforce our company’s commitment to customers who are increasingly seeking both cost-efficiency and sustainability,” said Gabriel Magdaleno, Strategic Product Management & Marketing director at Masterpress. “Enabled and supported by our hybrid printing technology, shrink sleeves are strategically positioned to meet these dual customer demands, while ensuring that brands stand out, communicate their identity and underline essential product information.

“We want to show our visitors that pursuing sustainability in packaging is not only possible but economically viable. Achieving this, however, depends on two key factors: cross-industry collaboration and innovation backed by leading research & development (R&D) infrastructure.

“We believe that the increased demand for innovative solutions, coupled with Europe’s new regulatory landscape, will be a strategic stimulus for closer partnerships within the sector and accelerate the sustainable packaging transition.”

View it all for yourself at Hall 5, Booth 5-161.

Bag-in-Box takes centre stage with Evopack and Tricor

Evopack and Tricor will showcase their bag-in-box formats, Boxli 1000 and the new Boxli 500, at this year’s show.

Compared to rigid packaging, the Boxli 1000 is expected to save 70% of CO2, storage, and transport costs. Furthermore, it is set to improve handling and product safety compared to conventional IBCs.

Meanwhile, Boxli 500 takes on a Euro pallet format (800 x 1200 mm) for 500L of water-based liquids. It caters to products filled in smaller quantities, or else to applications where logistics demand Euro pallet dimensions.

In either case, the Boxli system is recommended for any non-hazardous liquid, including paints, adhesives, binders, foods, pharmaceuticals, or even textile-related products. Each is believed to protect products against oxygen and tampering, thus reducing the amount of preservatives required.

Visit Evopack at Hall 3, Booth 521i.

SÜDPACK and SN Maschinenbau present mono-PE snack pouches

SÜDPACK will display mono-PE stand-up pouches for dry snack products, produced on SN Maschinenbau’s horizontal pouch packaging machine.

Made from Pure-Line, a tubular pouch film from SÜDPACK’s CarbonLite range of polyethylene and polypropylene-based films, the packs are recommended for various edible snacks, ranging from grated cheese and salami sticks to nut mixes and dog treats.

The pouches feature an integrated PE zipper and are believed to secure a long shelf life with oxygen and water vapour barriers, UV protection, and anti-fog features. No aluminium or metallization is required.

Additionally, their high thermal resistance is set to enable secure sealing for opening aids and reclose systems.

The packs are produced on SN Maschinenbau’s FME 50 horizontal pouch packaging machine, described as a ‘simple, flexible, and powerful’ model from its Economic Series. It offers a compact design and small footprint, with its fast and largely tool-free format changes set to facilitate easy operation, and is recommended for ‘nearly all’ dry food packaging applications.

Find SÜDPACK at Hall 1, Booth 317 to find out more.

Koehler unveils high-gloss, recyclable barrier paper with flex-crack resistance

Koehler’s NexPlus Seal Coat barrier paper will make its debut at Fachpack this year. Offering a glossy finish and ‘excellent’ flex-crack resistance, it is designed for recyclability – and has reportedly been awarded Interzero’s ‘Made for Recycling’ seal.

The material is designed to serve as an alternative to plastic packaging ‘wherever possible’. Compatible with flexographic, gravure, and digital printing, it utilizes a specially developed technology to achieve a high-gloss aesthetic and avoid cracking.

According to Koehler, NexPlus Seal Coat can be processed at the same speed as plastics on packaging machines, as well as being heat-sealable at lower temperatures.

“Countless brands want a recyclable mono-material that lets them showcase their products with a premium bold look featuring a high level of gloss that is perfect for the 95:5 rule – not to mention that they want it to be easily disposable as wastepaper,” says Christoph Wachter, director of Flexible Packaging Paper. “And that’s exactly what we’re giving them.”

Take a look for yourself at Hall 4A, Booth 324.

Norden presents high-speed NC100 cartoner at Coesia’s stand

The lineup at Coesia’s Fachpack booth will include Norden’s new NC100 cartoner, intended to handle up to 100 cartons per minute and maximize both efficiency and flexibility in the food, pharmaceutical, personal care, and consumer packaging sectors.

Due to its speed, the cartoner is set to unlock fast and repeatable changeovers. Up to 50 pre-programmed formats can be accessed via a 10-inch touchscreen HMI, and with its ergonomic material loading and ‘intuitive’ EasyWare II software, the machine is thought to minimize the required staff training.

Experts from Norden, Flexlink, AMACO, and Volpak will also be on hand to present Coesia’s developments in the automation space. They aim to highlight the company’s work to drive efficiency, flexibility, and long-term value creation across the consumer, healthcare, and industrial sectors.

To find out more, visit Coesia at Hall 3C, Booth 230.

Sidel to showcase smart palletising and packing solutions at Fachpack 2025

Sidel will be showcasing its range of packing and palletising tech for the food, home, and personal care sectors at Fachpack 2025.

“Packaging lines don’t evolve by chance - they need smart thinking and even smarter tech,” says Hervé Bour, Account Director for FHPC Eastern Europe at Sidel.

“That’s exactly what we’ll be bringing to FachPack: solutions that crush downtime, reduce operational overheads and unlock serious productivity gains.”

On stand C5107 in Hall 7, Sidel will spotlight innovations like RoboAccess_Pal S - a new online cobotic/robotic palletizing configurator that can apparently handle up to 2,400 products per hour, as well as 12 cycles per minute with payloads up to 25kg.

Also in the spotlight is CoboAccess_Pal, which Sidel hopes can answer manual palletising fatigue. The solution is being described as a safe, reliable cobot engineered to optimise end-of-line operations and to protect workers while accelerating throughput.

Focus on next-generation QR codes for Markem-Imaje at Fachpack

At stand 3C-531, Markem-Imaje will seek to demonstrate how the next generation of QR codes can enhance production efficiency, improve supply chain transparency, streamline inventory management and boost brand loyalty.

The company argues that ever-changing global regulations – such as the EU Digital Product Passport, Digital Deposit Return Schemes and the U.S. Food Safety Modernization Act – are accelerating the shift to 2D barcodes.

Markem-Imaje believes that the Digital Link, powered by GS1, is the next evolution of barcode technology. It connects the GS1 application identifiers for a specific product, such as the Global Trade Item Number (GTIN), batch number, best-before date and serial number, to the internet – enabling real-time access to both B2B and B2C information.

“The GS1 Digital Link barcode connects brands, retailers and consumers in a powerful ecosystem, unlocking new possibilities,” says Viktor Hermansson, Marketing Director at Markem-Imaje.

“While 1D and 2D barcodes will co-exist for some time, our mission is to support industry players through this transition with ease—from compliance to genuine consumer engagement.”

PPWR insights from Klöckner Pentaplast

Klöckner Pentaplast hopes to build on last year’s expert discussion sessions by sharing its unique insights on how to navigate the Plastic and Packaging Waste Regulation (PPWR) at Fachpack 2025.

KP will deliver expert-led, 20-minute presentations in Hall 4 on Booth 122, with six sessions in English and German planned across the three days.

The daily sessions will be held at KP’s booth at 11:30 (German) and 15:00 (English) on 23 and 24 September, and 09:30 (German) and 11:30 (English) on 25 September. There will be an opportunity to network immediately after the presentations.

Alongside the sessions, delegates visiting the booth will be able to learn about the company’s flagship products and latest innovations in an immersive packaging experience, using its Augmented Reality (AR) demo technology.

Mondi to showcase unique range of solutions at Fachpack 2025

At this year’s Fachpack, Mondi will showcase its innovative and diverse packaging range: from high-barrier solutions for pet food, food and home & personal care, to fibre-based alternatives for fast-moving consumer goods, solid board and corrugated solutions for eCommerce and industrial applications.

“Innovation at Mondi starts with collaboration,” says Thomas Ott, CEO Flexible Packaging at Mondi. “In our newly opened FlexStudios customers can actively participate in the innovation process, benefitting first-hand from our extensive expertise and state-of-the-art technology to drive sustainable change in the flexible packaging industry.

Another feature at the Mondi booth will be Mondi MatchMaker, the company’s start-up collaboration initiative. It connects early-stage innovators with Mondi’s business units through a structured framework that supports pilot development and scalable growth.

Mondi MatchMaker will be part of the panel discussion at FuturePack 2025 on 22 September, where early-stage founders have the opportunity connect with players in the packaging industry.

The company will also share a best practice example of its start-up initiative at the “Innovation in practice” networking event during Fachpack, on 23 September from 14-16 CET at INNOVATIONBOX.

You can visit Mondi at Hall 4, Booth 204.

Two Syntegon solutions in the spotlight at Fachpack 2025

With two major product highlights on display, Syntegon’s Fachpack presence will focus on production reliability, flexibility, and future viability.

At the heart of Syntegon’s booth is a vertical packaging machine that features a patented cross-seal drive. The SVX Agile aims to combine the “industry’s highest output” – up to 300 bags per minute – in a compact footprint.

The vertical form fill seal machine can process paper-based materials and mono films. Due to its modular design, it can be flexibly upgraded to meet future requirements. Built to package products from a wide range of industries, the SVX Agile offers functionalities such as easy washdown cleaning for the frozen food sector.

In addition to the SVX series, Syntegon will showcase the Kliklok ACC at FACHPACK – marking its first appearance at a European trade show.

This servo-driven carton closer was developed with the objective of providing precision and flexibility, processing a wide range of carton sizes and product types. With tool-free format changes, an integrated control system and energy-efficient drive technology, Syntegon says that the Kliklok ACC is aimed at companies that are looking to modernize their secondary packaging processes sustainably.

The machine can be integrated with other Syntegon components, such as the ACE carton erector, to form fully automated line solutions.

Head to Hall 1, Booth 257 to take a look at the above.

Focus on versality for Amcor at Fachpack

Highlights on Amcor’s Fachpack stand include the company’s recently launched range of reusable cups and lids; lightweighted food containers; latest closure innovations, including a new flip top closure for sauces; containers with recycled plastic and enhanced recyclability; and a wide selection of films for primary, secondary and tertiary packaging.

Amcor will also showcase its proprietary CleanStream technology – its domestically recovered, mechanically recycled polypropylene (PP) for contact-sensitive, homecare and industrial applications.

Meanwhile, the company will also be displaying its new reusable cups range that aims to meet increasing demand for alternative solutions to single-use packaging.

From an extensive closure range that includes a variety of flat caps and sports closures from 26mm to 48mm, Amcor will showcase the new Modena Flip Top TE (tamper-evident) closure, which has been designed to offer a versatile and more sustainable closure for vinegar, sauces and dressings.

Other closure innovations on display include the lightweight Sava Flip Top for sauces and dressings, and the Sunny and Pical Pouring closures, developed for edible oils and featuring a variety of orifice sizes and styles to suit different product characteristics.

Another solution on display will be Amcor’s Politainer, which seeks to offer safe and effective transportation for products such as inks, chemicals, pharmaceuticals, foods, and cosmetics.

For pallet protection, Amcor will present Stretch Hood films – a high-performance solution engineered to secure loads across a wide range of challenging applications.

And for pallet stabilization, Amcor will showcase its Bontite and Stratos stretch wrap films. Bontite, a blown film, is engineered for high-speed, high-volume applications, delivering up to 300% stretch with excellent puncture and tear resistance for secure load containment.

Omni Xtra+ cling film – a recycle-ready polyethylene alternative to PVC cling film, reportedly offering high clarity, anti-fog performance, and strong shelf presence – and collation shrink films designed to deliver secure pack integrity with the option of including PCR content will also be demonstrated at the show.

Amcor’s solutions will be demonstrated at Stand 310, Hall 6.

UPM Specialty Papers to display new co-created recyclable packaging solutions at Fachpack

At Fachpack, visitors will have the opportunity to explore UPM’s portfolio of fibre-based, recyclable packaging papers.

The company’s solutions developed alongside Royal Vaassen will be on display – these are recyclable, food-safe barrier paper solutions designed for a range of end-use applications, from medium to high barrier requirements, including cannister applications.

UPM Specialty Papers’ recyclable paper chocolate wrapper will also be available to view. This pack protects the contents from oxygen and grease, while maintaining the efficiency of the packaging line.

Also on display will be the company’s collaborative project with BOBST and Michelman – an innovative, high-barrier, recyclable paper-based packaging solution that aims to offer an alternative to multi-laminate structures. It is especially designed for long shelf-life products such as coffee, spices and other demanding end-uses.

UPM will be located at stand 329 in hall 3A at Fachpack.

No comments yet