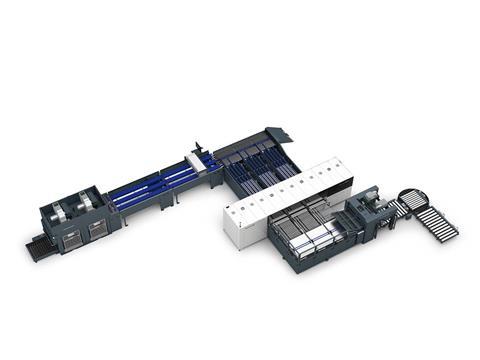

Koenig & Bauer has launched a new digital printing press that it says is the first such solution that can be integrated into a production line for metal decorating.

The basis of the MetJET ONE combines proven components from digital printing as well as sheet handling and system engineering for metal decoration. The sheet handling system is made by Koenig & Bauer MetalPrint, while the integrated inkjet technology is based on a multi-pass printing unit from Durst.

“The MetJET ONE makes it as easy as possible for our customers to enter the world of digitally printed metal packaging,” explains Samuel Teufel, Product Manager at Koenig & Bauer MetalPrint. “The unique design enables us to create a customised solution that fits the flexibility and print quality requirements of our customers in the metal packaging industry.”

K&B says that the modularity of the MetJET ONE enables flexible customisation and design of the entire production line to meet the demands of the packaging industry.

This means that the line can be equipped with the entire Koenig & Bauer MetalPrint portfolio in addition to the basic units. The company says that the MetalCoat coating machine, the inspection transport for checking the image (and overprint varnish) and the sheet management systems for reliable sheet ejection are just some of the possible features where efficiency and profitability can be maximised on the MetJET ONE.

The machine will start a field test at the beginning of 2025 in cooperation with Reynolds Services, Inc – a crucial step in validating the machine’s performance and reliability under real operating conditions.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

The ultimate guide to global plastic sustainability regulation

No comments yet