Aeropowder, which supplies solutions made from surplus feathers as an alternative to single-use plastics and other materials, has announced that it has secured a £150,000 investment from manufacturing investor British Design Fund.

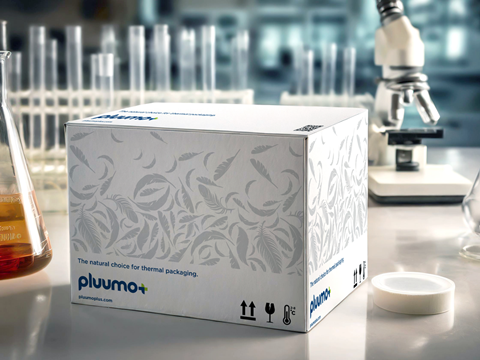

The cash injection will be used to support the launch of the company’s thermal packaging product, PluumoPlus, which is designed for the life sciences industry and cold chain logistics. Aeropowder states that traditionally, plastic materials, such as expanded polystyrene, have been relied upon for the storage and movement of temperature-sensitive goods – adding that its solution is able to maintain an internal temperature of between 2-8°C for over 72 hours, even when external temperatures average 30°C for the period.

Co-founder and biologist, Dr Ryan Robinson, began working on the innovation while completing his PhD at Imperial College London. He joined a research project exploring novel uses for feathers that harness their natural properties, while reducing waste. Aeropowder claims that an estimated 3 million tons of waste feathers are generated every year in Europe, which are either incinerated or turned into low-grade animal feed.

Robinson explained: “The world needs more novel materials, processes and solutions to combat the pressing environmental and economic challenges that we face. Looking at natural ecosystems for inspiration, which inherently are more sustainable and resilient, it’s clear that concepts such as the circular economy have a massive role to play – essentially, how we minimize or repurpose waste streams in more productive ways.”

Aeropowder’s future product developments are set to include acoustic panels and other building insulation materials. The company’s second patent focuses on oil absorption materials, designed to help clean up environmental spillages without resorting to plastic foams.

In related news, ice pack sealing technology from Hydropac seeks to enhance the cold chain logistics of pet food by improving insulation, increasing leak resistance, and keeping temperature-sensitive products cooler for longer. The technology is designed to achieve leak resistance, and its burst strength has been tested to over 200kg.

Groenlandia Tech and Inokor in Spain have partnered to create a temperature-controlled cooler, Nuük, designed to transport products or samples in the hospital and pharmaceutical sectors with real-time sample tracking and total access control. The container is made from ARPRO EPP as it apparently offers thermal insulation and energy absorption properties.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

The ultimate guide to global plastic sustainability regulation

No comments yet