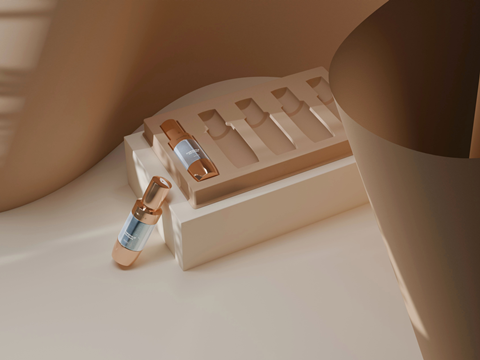

Scanfill and Sulapac present a compostable wood composite-based thermoforming foil that serves as a ‘drop-in’ alternative to conventional plastic foils.

Made from the Sulapac Flow 1.7 wood composite, the Degrafoil Flow 1.7 is intended as an alternative to traditional plastic solutions. Due to its high biobased content, it is said to lower a pack’s carbon footprint ‘significantly’ compared to solutions such as PET.

The foil is thought to offer the functionality, scratch resistance, and durability of plastic, but help manufacturers replace their oil-based polymers in thermoforming processes – all while continuing with ‘business as usual’.

Apparently, the solution unlocks ‘consistent’ quality and ‘easy’ processability in thermoforming, and the final product has a smooth, ‘fibre-like’ texture that is distinguishable from plastic film. It is also said to offer ‘limitless’ colour customization.

Degrafoil Flow 1.7 is produced at Scanfill’s facility in southern Sweden, and it is claimed to adhere to requirements for food-contact materials.

Scanfill and Sulapac aim to help European thermoformers meet increasing customer demand for sustainability-minded packaging solutions without impacting quality or manufacturing performance. In turn, they aspire to contribute to a green transition in Europe’s packaging industry.

“For a long time, we’ve wanted to include a compostable alternative in our portfolio, but only Sulapac managed to meet our quality requirements,” says Karl Banke, sustainability specialist and technical support at Scanfill. “With Degrafoil Flow 1.7, our clients can respond to brand owners’ increasing demand for renewable content and reduced carbon footprint – while continuing business as usual.”

“Sulapac always aims to make sustainability an easy choice,” continues Juho Luukkanen, sales director at Sulapac. “That way, we can ensure our innovations spread widely and create meaningful impact.

“Together with Scanfill, which has a broad customer base and strong sales capabilities across Europe, we can accelerate towards that goal.”

“Customers value Flow 1.7 for its uncompromising nature,” adds Niklas Linde, Sales at Scanfill.

In similar news, Sustainability Awards 2024 finalist COPAR previously packaged meat in thermoformed wheat straw trays, aiming for both recyclability and compostability.

Amcor Capsules and Moët & Chandon also developed a plastic-free foil made of aluminum and paper, targeting improved recyclability and a decreased carbon footprint compared to conventional solutions.

Since then, ITC Packaging’s thermoformed CombiCup has combined cardboard components with separable and recyclable plastic to form a cup for hot and cold, ready-to-drink and dairy products.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet