Minebea Intec, formerly known as Sartorius Intec, has expanded its foreign body detection product range with the recent introduction of two new X-ray inspection systems Dymond Bulk and Dylight.

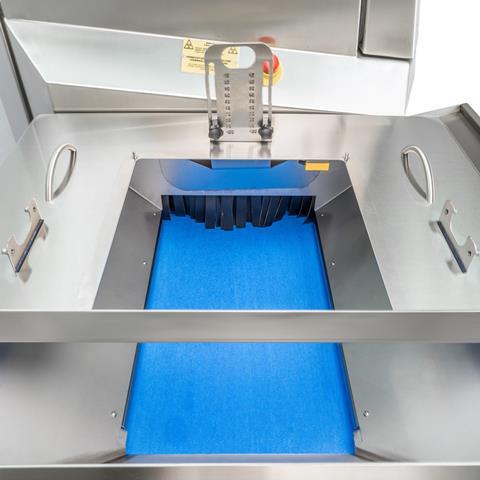

The supplier of industrial weighing and inspection technologies developed the innovative system Dymond Bulk specifically with bulk goods in mind. The X-ray inspection device is particularly suitable for processes between incoming goods and packaging lines in the food industry. The X-ray inspection system Dylight is pitched as a high quality entry level system offering a wide range of uses in the packaging line. The 'Plug and Play' solution is simple to position and requires a minimum space of 1000 mm in line layout. Both systems guarantee reliable detection of metal, stone, plastic, bone and glass foreign bodies and eliminate any foreign bodies they identify.

Dymond Bulk inspects bulk goods like nuts, smaller fruits, frozen vegetables, and also spices, coffee and seeds. The solution also identifies bits of dirt and glass, which has obvious benefits for all goods that are introduced into the production process 'straight from the field'.

“In food production, the ‘sorting and cleaning’ stage for raw materials is by no means a precise science” explained global product manager, Inspection, Torsten Schmitz. “The X-ray inspection system Dymond Bulk can make a significant difference here, increasing safety and quality parameters even before the refinement process.”

Dylight is perfectly suited to the inspection of small and light foodstuffs, such as snacks, energy bars, sweets and crisps. The system boasts a high level of efficiency and saves valuable space on the production line thanks to its compact design. All the required functions - including a blower for separation and a run-off container – are combined in one compact unit that takes up a width of just one metre. The system is easy to maintain. An intuitive user interface reduces operating errors to a minimum, new products can be configured quickly and conveniently.