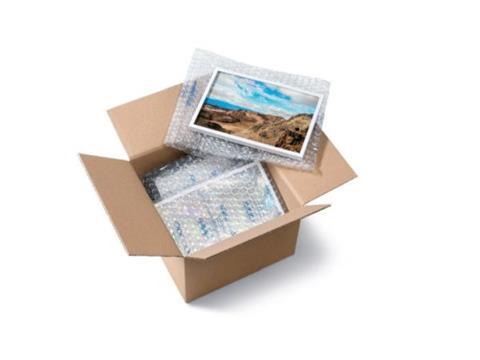

The protective packaging specialist Storopack has added a space-saving substitute for traditional bubble wrap to its portfolio, with AIRplus® Wrap film. Thanks to its innovative format, AIRplus® Wrap film lends itself especially well to wrapping delicate products: its flexible, wave-like structure allows items to be wrapped tightly.

As a result, fragile and delicate products of varying sizes are now even better protected from shocks, scratches and damage. Another advantage is its on-demand production, with the packer creating the air pillows according to their needs directly at the packing station. This gives it the edge over ready-inflated bubble wrap which is delivered on large rolls, takes up a lot of storage space and has to be continuously transported to the packing station.

AIRplus® Wrap film can be produced on the compact Storopack machine systems AIRplus® Mini and AIRplus® GTI, and is available in two formats: 400 × 175 millimetres (wrap film 19d) and 710 × 175 millimetres (wrap film 36d). The wrap is particularly suited to fragile products and items which are not pre-packaged. It only takes a few manual moves to cover an item in the wrap.

Low process and storage costs ‘The aim in developing AIRplus® Wrap film was to wrap items even more tightly, for greater product protection. We have achieved this thanks to its special wave-like structure. The film is also a clever alternative for wholesalers and producers who still rely on large rolls of ready-inflated bubble wrap,’ says Michael Spicker, AIR product manager at Storopack. ‘This is because process and storage costs can be reduced by only producing air pillows according to requirements directly at the packing station.’ AIRplus® Wrap film joins the existing portfolio of AIRplus® products, including Void for large air pillows used to fill voids, Cushion with smaller air pillows for blocking and bracing and for cushioning, and Bubble with round air chambers for wrapping items: all of these wraps can be produced directly at the packing station and can therefore be easily incorporated into any packing process.

More info: