In a series of 5 Innovation Spotlight articles, AG Solution goes beyond the buzzwords and explains how a digitalization journey can be a means to dealing with very practical problems and challenges in your specific environment. In the first article of the series, AG Solution will focus on weighing and dispensing.

MES (Manufacturing Execution Systems) is all about managing the production and ensuring the product quality. The quality of a product is directly related to its physical composition. Dosing the right quantities for the right products is of critical importance. There are plenty of tools available for this purpose, but without integration into the rest of the MES modules and the organization’s entire digital infrastructure, the added value remains limited.

The traditional tools to support and maintain weigh and dispense processes have served their purpose in an analog and non-integrated world. But with the increasing pressure on accuracy and speed of the manufacturing processes, they are found severely lacking.

An organization with several manufacturing plants, often finds itself coping with distributed and heterogenous business rules for the weigh and dispense (W&D) order management. Moreover, the lack of maintained and documented W&D operations is likely to repeatedly cause mistakes: dispensing incorrect lots, omitting consumption strategies (such as FIFO).

Poorly digitalized and insufficiently integrated W&D units cause a lot of inefficiencies: excessive paperwork, poor management of W&D processes and workflow steps – which leads to mistakes such as product re-processings and product waste, and process variability.

All the above also leads to a poor and inefficient traceability system. And the manual integration of W&D with ERP systems and OT systems (such as weighing devices) is very likely to generate human errors which can seriously disrupt the supply chain and to slow down the manufacturing process.

Automation, homogenization and integration: a cure for the pain

All of the above problems and inefficiencies can be solved with a well-developed and well-integrated MES Weigh & Dispense module, which can also standardize and homogenize the weighing and dispensing activities. A modern, well-connected and integrated MES W&D module should include:

- Management and execution of all weigh and dispense processes from a central controlling environment.

- Guidance for the W&D operators through well-defined and centrally maintained workflows (manufacturing business rules), including Standard Operating Procedures

- Tracking of all activities involved

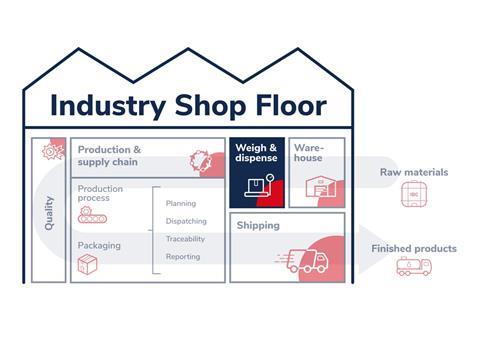

- Integration with the shopfloor

- Control and visibility of inventory levels

- Reporting capabilities

- Verification by wireless handheld devices

- Centralized and controlled master data about all materials (BOM – bill of materials)

- Automatic label printing

Increase in quality, efficiency and revenue

A well-developed and well-integrated W&D module will benefit the business on many levels. Planning and scheduling will be enhanced and can be priority-based. As the W&D business rules will be automated and maintained, there will be no more need for paper validation.

The digitization of data and processes ensures more efficient processes and traceability, while saving your organisation valuable time and reducing the risk of human errors. Last but not least: by introducing a consistent weighing process, you can achieve an optimal level of quality.

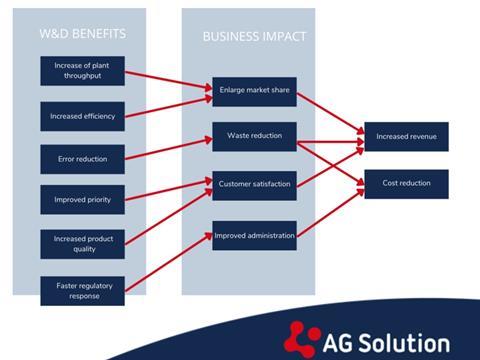

Below you can see how various advantages can ultimately be translated into an improvement of the bottom line, by increasing the revenue and reducing the costs:

Benefits across departments

This graph also illustrates how the benefits can be experienced in various departments.

The production department enjoys waste reduction, improved lead times and process optimization. The continuous improvement department will be able to better benchmark processes, and can better detect opportunities for investments. The Quality Assurance department are given the right basis to achieve traceability and end-to-end genealogy, to improve the workflow edition and approval process, and – in some industries - to react more swiftly and easily to audits from regulatory agencies. Lastly, the supply chain department are provided with the right data to better benchmark for applicable supply chain metrics such as lead times and throughput, and with solid metrics for their materials preparation.

Summarizing, a well-integrated MES W&D module will homogenize, standardize and centralize all data and processes in order to increase efficiency and quality of the manufactured products. Additionally, it will provide all parties concerned with relevant data, which leads to yet more business improvement. Thus, the W&D module becomes a significant contributor to the overall business result.

MES Weigh and Dispense is the first article in a 5-article series illustrating how MES can contribute to your digitalization strategy. In our next article, we will focus on Quality.

Can’t wait to digitalize your weigh & dispense processes? Contact us today and our experts will help you get started.

This content was sponsored by AG Solution.