In a series of 5 Innovation Spotlight articles, AG Solution goes beyond the buzzwords and explains how a digitalization journey can be a means to dealing with very practical problems and challenges in your specific environment. In this edition, we focus on planning and dispatching.

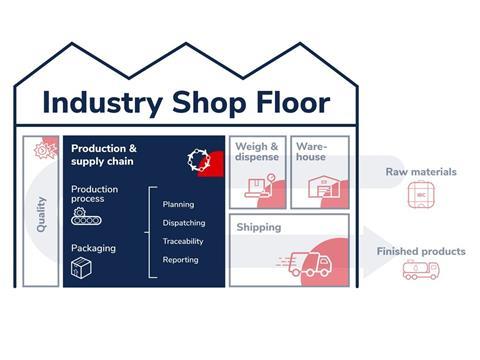

MES is all about managing and orchestrating all manufacturing activities, ensuring product quality.

But increasingly, organizations are expecting a detailed and complete insight into the production data, during and after the production. This can only be realized by connecting the MES system with all relevant data sources. A complex but worthwhile endeavour.

In theory, it is not so hard to draw up an ideal plan. But in practice, you find yourself constrained by other business realities such as (un)timely delivery of goods or cost optimization.

These factors and others generate a consistent trade-off in planning between efficiency and delivery: you want the production to start as soon as possible, but you also want to optimize the production to minimize the required service activities, such as cleaning and line setup, and to reduce changeover. This requires a comprehensive and up-to-date overview of all the resources needed (human, asset, or material). In addition, you need to be able to easily reallocate and recalculate these resources depending on plant availabilities.

Once all resources are available, you need to dispatch production as soon as possible.

But very often, this process is hindered by the slow communication process (over the phone and other non-integrated means of communication) needed to confirm this availability. Meanwhile, you need to ensure that all internal and external conditions are met (cleaning of equipment, security checks, etc.) before launching the production. Failure to do so can create product flaws, rework or other major issues.

Moreover, a lack of overview and poor management of materials may result in products staying in the warehouse for a very long time or even result in unused raw materials needing to be returned from the dispensing area to the warehouse. This leads to higher inventory costs, which should be avoided at all times.

Accurate, detailed, up-to-date and integrated information is key

Optimizing the planning and dispatching processes for an ideal business result is a challenging task, that much is obvious by now. An ongoing task, which can fortunately be simplified and supported by a reliable and integrated MES solution.

This solution should be able to calculate, among others, the production setup and processing time. It should be well integrated with the other MES modules, for instance, to obtain the required information to make recipe-based calculations and predictions regarding availability of resources. Integration with other systems, such as the ERP software, helps in planning the production based on expected delivery of materials.

The solution should feature an advanced scheduling function, which will schedule the processes by using real-time data and multiple plant constraints. Last but not least, it should present all data within a user-friendly user interface, thus providing visibility in a complex environment.

The access to the scheduler can also be role-based, depending on the type of user, thus providing the user with the exact information they need at any moment.

On the dispatching side, the software should have an overview of the availability of products and materials, but also of the human resources required for the production and of the production lines, machines, and other assets involved in the production.

As discussed above, it should be aware of the composition of raw materials and of finished goods, and of the recipe to produce them. This enables the system to detect potential shortages and to predict and plan the production in terms of the future availability of resources.

MES planning & dispatching: a powerful optimization tool

With such a MES module at your fingertips, optimizing the planning and dispatching processes becomes a lot more powerful.

Based on accurate schedules for raw material supply and for machine setup, you can make more accurate and reliable plans, and set realistic start and finish dates for each work order. You can better calculate the cost of the plans and assess the probability of meeting the objectives for each and every plan.

Based on the actual timing, you can also improve the reliability of this assessment, by adjusting the processing time and other variables. And you can optimize the available lot based on comprehensive and detailed information on the entire manufacturing process.

In terms of dispatching, you can reduce cycle times by improving the dispatching velocity: a proactive system to alert and to advise on the next step replaces the numerous calls and emails of the past, and digitally checks the availability of assets taking coded business rules into account. The accurate overview of all needed materials provides you with a good insight into the availability and real-time status of products. This not only reduces the time-to-market, but it also increases the number of on-time deliveries.

Meanwhile, the timing of the deliveries improves, because the proactive system can dynamically calculate delivery times at each step, and warn when theoretical delivery times will not be met according to standardized processing times. This will undoubtedly have a positive impact on your customer relations as well.

All of the above contributes to the bottom line in various ways. Additionally, the tight control and accurate overview, combined with the standardized and centrally maintained standard operating procedures (SOPs), significantly reduce the number of mistakes in the manufacturing process. The use of an integrated MES module for planning and dispatching will pay for itself sooner than you might imagine.

MES Planning and Dispatching is the second article in a 5-article series illustrating how MES can contribute to your digitalization strategy. In our next article, we will focus on Product Tracking & Tracing.

Can’t wait to digitalize your planning and dispatching process? Contact us today and our experts will help you get started.

This content is sponsored by AG Solution.