Petr Franc, divisional director for security at IQ Structures, discusses the increasing sophistication of hologram technology and how it can be used for brand protection as well as decoration.

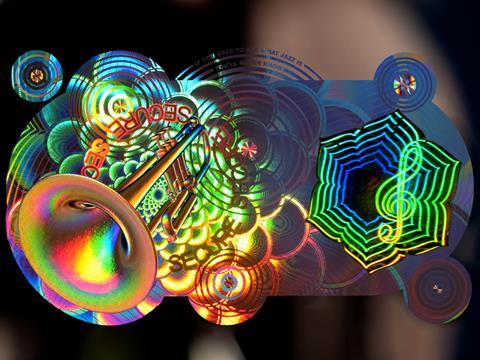

Some six months ago, it was announced that my colleagues from IQ Structures had introduced technology for embossing holograms in vinyl records, in the sound carrying areas. This is fascinating from a decorative point of view because it changes a traditional record into a luxury item. However, it is also interesting as a part of a massive trend that reshapes the entire industry of anti-counterfeit protection.

This innovation is in line with long-term developments in packaging and brand protection:

- Protection elements are more and more sophisticated

- Their integration with protected items is coming closer and closer

- Protection elements include more and more technologies.

It will be demonstrated in the following article that hologram mastering is the key to success in this area. Mastering means creation of master holograms, the diffraction structures that reflect light so that required optical effects arise.

Protection elements

The history of brand protection is more than 100 years old. It appeared immediately after mass production and transport overcame the barriers of local economies. The brand marks became more and more sophisticated and counterfeiting resistant. In the 1980s, the first protection holograms were applied. It was a breakthrough innovation, although the holograms were very basic from today´s point of view. Several generations of holograms have emerged since that. Now we can differentiate several levels of holograms.

BASIC

Their security level is quite low because they can be imitated even by students. Typical example is a flip-flow effect, monochromatic switching between two motifs, e.g. between a logo and digits.

ADVANCED

Their security level is significantly higher. It is possible that a sophisticated attacker could produce something that looks similar but it would be costly and laborious. A typical example is a dim 3D object with a bright object inside.

SOPHISTICATED

It is virtually impossible to imitate them. An example is an extremely bright bas-relief effect.

UNIQUE

Such holograms include visual effects that can be produced by only a single laboratory around the world. In addition to expensive equipment, you need also tailored mathematic algorithms. The typical example is colour imaging with white light sources

Integration with protected items

The latest trend is towards placing holograms directly on protected items, not through a label but directly onto its substance. To reach this, several technical challenges need to be met.

- Origination: It is important to define the visual effect suitable for different items and materials. It is a reason why IQ Structures´ mastering centre employs both technical scientists and art designers. But it is even more critical to create a diffraction structure that 'walks together' with the substance. This requirement gives significant advantages to those manufacturers that combine different mastering technologies, such as laser, electron-beam, nanoprinting, etc.

- Transferring the hologram onto the item, through embossing, casting, engraving, metallising or any other technology: Each substance has its special features that need to be taken into consideration. Even if a similar application already exists, technology will likely need tuning. Laboratories that have previously worked with different substances have a significant advantage. Their experience can help determine the time and costs of the project.

- Mass replication issue: There can be a quite long way from getting the hologram on the item during development to mass production with many imperfections and time pressure. The operations, which include high temperature or mechanical stress, often appear during the production cycle. This can influence the substance´s ability to keep diffraction grating.

- Production cycle planning must also be included in the preparation: What company should perform what operations? How should be the process be managed and coordinated? Sometimes it is not easy to find an arrangement that is cost-effective, simple and secure. There are a lot of options, from delivering master holograms and technological instructions up to integrated production. In any case, it is very useful if the holographic technology provider manages its processes exactly. To demonstrate this, IQ Structures has been ISO certified and we are preparing for other certifications.

Integration with other technologies

The integration of holographic protection with other measures is also a long-term trend. The serial number can be written in the hologram, a QR code can be included, or another connection to a track & trace system.

Mobile phone verification is the latest hit. The user can read the element with his/her smartphone and get confirmation of authenticity immediately.

It is still not the end. You can bet that new types of counterfeiting attacks will emerge, as well as more sophisticated protection technologies. However, it is very unlikely that the basic trend will reverse. The holograms will be more and more sophisticated and embossed directly on the substance. The stickers are useful for the time being, but their use will be more and more limited.