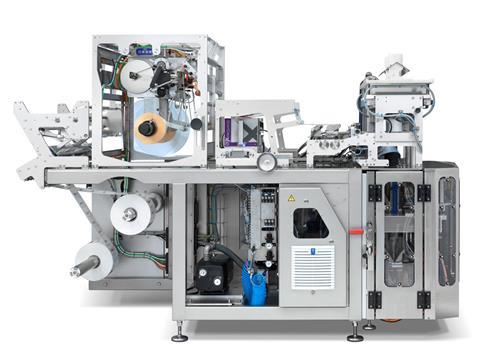

GEA, one of the largest suppliers of packaging and processing solutions for food, has launched its new SmartPacker TwinTube vertical packaging machine in Europe.

The entire machine has been redesigned as a modular system with increased functional efficiency reportedly promoting higher operational uptime and ease of use. GEA reports that the updated version reduces operational costs and energy use thanks to sealing technology advances. Plastic, as well as functional paper, can be used for bag production.

The TwinTube is a continuous motion vertical machine, suitable for packaging small-sized food products such as candy, nuts, and dried fruits and other on-the-go products in pillow bags of different sizes. The machine is part of a complete packaging process with upstream and downstream equipment operating in a dry manufacturing facility. It operates with two parallel forming tubes, apparently achieving combined speeds of up to 500 bags per minute (weighing 10 to 18 g each). It is also possible to run a different film reel for each tube, meaning calorie packs of different widths or designs can be simultaneously filled. A new feature to the machine is the Jumbo Roll, which, according to GEA, allows film reels of up to 100 kg to be used for long production runs, which boosts operational efficiency.

“The new TwinTube has a modular construction that allows customers to easily add new options and upgrade their machine, thus prolonging the life span of the system. In addition, we’ve increased operator friendliness by introducing toolless adjustment features which helps achieve shorter change-over times and proven/error-free setup of the machine – this includes printers, labelers, and the vertical sealing unit,” explains Martijn van de Mortel, Product Manager Vertical Packaging at GEA. “With these new updates, we’re able to meet our customers’ demands in terms of automated process control, less operator dependence, more uptime, and operational efficiency,” he adds.