In our latest Finalist Interview for the Sustainability Awards we spoke to Plastiques Venthenat about its collective project with Citeo, Olga, Amcor, CEDAP and Synerlink to produce the Fully Recyclable Ready yogurt FFS pack, nominated in the pre-commercialized Recyclable Packaging category.

You’re a finalist in the Sustainability Awards 2023. Congratulations! To start off, could you summarise your entry, in less than 50 words?

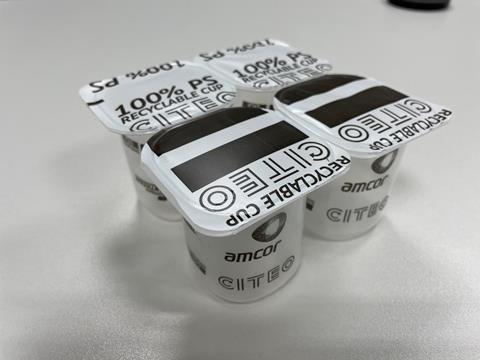

The development of the Fully Recyclable Ready Polystyrene Yogurt FFS [Form-Fill-Seal] pack is an eco-design project elected by Citeo, the French EPR [Extended Producer Responsibility] done by a collective working group: Olga (French yogurt producer); Plastiques Venthenat (film producer); Amcor (flexible packaging); CEDAP (polystyrene sheet) and ARCIL Synerlink (FFS machine).

Why do you think the judges were impressed with your entry? Tell us about what is innovative about your project and/or about its impact on packaging sustainability.

Yoghurt cup packaging made of single (98.5%) raw material polystyrene is a worldwide innovation. This new Fully Recyclable Ready Polystyrene Yogurt FFS pack will optimise the efficiency of the whole recycling chain process, from sorting to new recycled material applications.

It will allow yoghurt producers to claim their packaging is fully recyclable (French decree) thanks to the new polystyrene recycling stream. It is going to help and foster the growing investment in new polystyrene recycling plants in Europe. The pack offers the yogurts and desserts category a packaging solution entering the circular economy at scale!

The ‘single polystyrene recyclable cup’ innovation should send a strong signal to the market of the need to create a circular packaging loop, convince the end user of the necessity of sorting, accelerate investments in polymer recycling plants and contribute to the reduction of fossil-based plastic.

When and how do you intend to launch/commercialise this innovation?

The launch will be related to the industrial European Polystyrene recycling stream expected to be industrial by mid-2024. The end of 2024 is also the deadline to comply with the French regulation allowing polymer packaging if it is recyclable. At that time, yogurt producers will be allowed to promote a full recyclable packaging communication to their customers with an emblematic product used every day.

You’re shortlisted for the pre-commercialised category for Recyclable Packaging. What do you see as the key demands and challenges in relation to design for circularity in packaging?

Eco-designed packaging for circularity has two main challenges. The packaging should be done with a single raw material (with a target of over 95%) for offering recycling efficiency and reaching the circular loop, and it should match with the development of the industrial recycling stream.

What do you think are the main opportunities in this area or what future innovations do you predict in this area?

We are convinced that more mono-material packaging will be launched in the near future. This will help with the creation of multiple recycling stream plants by offering them eco-friendly packaging that can be easily recycled.

The consequence will be the development of raw material coming from these circular loops with food contact applications. We strongly think these conditions will be the only way to keep or recreate the trust of the end user in packaging.

The winners of the Sustainability Awards 2023 will be announced at the Sustainable Packaging Summit, which takes place in Amsterdam on 14-15 November. The Summit mobilizes leaders of the FMCG value chain, policymakers, NGOs, recyclers and investors to collaborate, remove barriers and identify opportunities on the road to sustainable transformation.

To learn more or register, visit https://www.packagingsummit.earth/amsterdam2023/.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

What steps is Apple taking to make its packaging more sustainable?

How did Brazil achieve its 100% aluminium can recycling rate – and can it be replicated in the EU?

Experts have their say on the EU’s Packaging and Packaging Waste Directive revisions

No comments yet