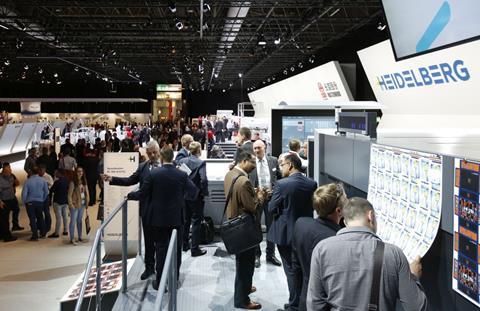

After an eventful drupa 2024, we take a look back at the printing exhibition’s first week, explore some key trends and developments and shine a spotlight on just some of the product launches in the area of packaging printing, in particular in the machinery space.

Around 170.000 visitors attended drupa 2024 – a reported 30% drop in visitors compared to 2016, reflecting ongoing consolidation in the print industry. Packaging printing, however, bucks this trend. According to a report from Smithers, the packaging printing industry will reach a worth of $551.3 billion by 2027 with a growth rate of 3.1%.

The share of exhibitors active in the packaging industry reportedly increased “significantly” at drupa and was the focus of many exhibitors as a growth driver.

Despite the drop in visitor numbers, key players, such as Bobst, Canon, Fujifilm, Heidelberger Druckmaschinen, HP, Horizon, Koenig & Bauer, Komori Konica Minolta, Kurz and Landa, reported having signed contracts that “exceeded expectations”.

Digitalisation and automation took centre stage, with a strong focus on AI and smart workflows and software solutions. Robotic solutions were omnipresent and showcased the path towards the smart factory.

Packaging sustainability was another key trend addressed at the show by events such as Touchpoint Sustainability and Touchpoint Packaging and many of the innovations launched at the event.

Look out for an in-depth article on Touchpoint Packaging on our website coming soon!

Spotlight on innovation

drupa 2024 saw various product launches – we shine a spotlight on just a few of them.

Gallus Group/Heidelberger Druckmaschinen AG

Gallus Group, a subsidiary of Heidelberger Druckmaschinen AG, announced its new “System to Compose” concept at drupa. The new concept sets out to address current and evolving market needs for label printers and reportedly offers full adaptability, whereby additional units reportedly can be seamlessly added, removed or replaced.

In addition, it was announced that the Gallus One, previously limited to a print width of 340mm, is now also available in a print width of 440mm. Finally, Gallus also unveiled an enhanced colour gamut for the Gallus One, with the introduction of orange and violet inks.

Following the market launch of the Boardmaster, Heidelberger Druckmaschinen AG is planning to extend the range of applications for this new inline flexographic web printing system to flexible paper packaging in the medium term.

“The global increase in demand for sustainably produced, budget-friendly, and recyclable or compostable packaging makes flexible paper an attractive growth market for us,” says Christian Steinmassl, in charge of the packaging segment at HEIDELBERG. A complete Boardmaster will be available for customer demonstrations in the Print Media Center (PMC) at the HEIDELBERG Wiesloch-Walldorf site from drupa 2024 onward.

The Boardmaster is available in a total of four printing widths ranging from 850 through to 1,650 mm. When developing the system, the company focused on the key challenges and requirements of its customers – significant cost pressures, quality and operational reliability, sustainability, and high investment security. “A high degree of automation and simple operation support production with low staffing levels. This also counteracts the shortage of operating personnel. Last but least, the AI-supported printing plate and sleeve scanner Intellimatch helps ensure print results meet high quality standards,” adds Mr. Steinmassl.

Canon

As part of its commitment of becoming a “significant, trusted partner to the label and packaging markets”, Canon gave its first live demonstration outside Japan of the new LabelStream LS2000 water-based digital label press, slated for 2025 availability at drupa. Through a 3D model, technology animations and production samples, Canon also showcased its concept for a 1.7m wide, single pass, industrial-scale corrugated press, offering a production speed of 8,000 sqm/hour at offset quality.

Xeikon

Xeikon launched the Xeikon PX3300HD, a new 1200 dpi digital press at drupa 2024. Developed for high quality labels, the company says that the five-colour machine offers a 330mm printing width and speeds up to 70 m/min, even when printing with high opacity white. In addition, Xeikon PX3300HD utilizes a newly developed ink series, PX-Cure LED HD, to ensure “perfect” curing, while supporting sustainability targets for converters. The machine will complement the existing 600 dpi product range, say Jeroen Van Bauwel, Director Solution Design.

To meet the specific requirements of the higher resolution engine, Xeikon has developed new PX-Cure LED HD inks. The new inks match the sustainability benefits of the recently introduced PantherCure UV LED series for Xeikon 600-dpi inkjet presses, including savings in energy consumption, instant warm up for more agile operation, and “ten times longer” lamp life compared to traditional UV arc lamps, resulting in lower waste.

Bobst Group

BOBST Group focused on a “new era” in packaging where the entire production line is connected, enabling seamless end-to-end workflows based on the pillars of “connectivity, digitalization, automation and sustainability”, as the company’s CEO Jean-Pascal Bobst pointed out.

BOBST recently entered into a strategic partnership with Packitoo, a French company developing digital solutions in the packaging industry. The partnership aligns with BOBST’s strategy to digitalize and connect the entire packaging value chain.

Presented at drupa, the DIGITAL MASTER 55 is described as an “all-in-one digital printing and converting platform tailored for the folding carton industry” for short-to-mid-size runs.

It combines printing, embellishment, quality control, and die-cutting inline at 100 mpm. By enabling just-in-time production, it sets out to minimize the need for large stocks and inventories.

In the packaging sector, BOBST focuses on connectivity by enabling a closed-loop workflow ecosystem. New features of BOBST Connect – the cloud-based digital platform - include an update to equipment monitoring, providing more detailed data insights, while performance management provides insights on equipment, shift and job performance and energy consumption, optimizing sustainability and cost.

For labels, the new cloud based BOBST’s Digital Front End (DFE) 3.0 was showcased for the first time to the public and will be commercially available later in the year.

It reportedly enables access to real-time data, resources and workflow templates. Colour management can be managed centrally and shared in the cloud, and its web-based interface supports multiple users across multiple sites.

On the ink side, BOBST showcased Thalia ink, UV digital inks designed to meet the highest standards in ink compliance. They are described as TPO free, and compliant with major regulations including REACH and EuPIA GMP. BOBST Thalia inks are without any CMRs (carcinogens, mutagens or reproductive toxins) and are compliant with the latest Swiss Ordinance announced in February 2024. In addition, the new ink set reportedly has better resistance performance and improved colour gamut.

Specifically for the folding carton industry, the Thalia Foldable UV inks address the foldability challenge of high ink coverage or dark colour applications.

Also in the area of folding cartons, BOBST launched a new version of its flagship flatbed die-cutter, the MASTERCUT 165 PER. Able to handle corrugated board and folding carton, the machine delivers “perfect” batches or pallets of blanks thanks to its novel Dual Stream system. A new carbon gripper bar enables an increased running speed of up to 7,500 sheets per hour, while in-line quality control with automatic waste ejection delivers zero-fault packaging.

Scodix

Just ahead of drupa, provider of digital embellishment solutions Scodix announced the launch of two new presses, the Scodix Ultra 2500 SHD and the Scodix Ultra 6500 SHD. In addition to these presses, Scodix brings AI to print embellishment with an automated embellishment creator tool, Scodix AI. The two new presses see the debut of Scodix MLE (Multi-layer Enhancement) and are engineered with Scodix SHD (Smart High Definition) technology.

Scodix MLE reportedly opens a “new dimension” for embellishments on uncoated paper that is recyclable and repulpableThe key to Scodix MLE is the ability to apply multiple Scodix layers in a single pass. For uncoated paper, the first layer acts as a selective micro coating primer before Scodix Foil™ or Scodix Sense™. With the flexibility to add layering, braille and crystal effects become more economical.

In addition, both presses deliver increased automation and reduce the cost-per-page for incorporating value-added enhancement into printed products and feature AI technology for automating embellishment additions.

EFI

EFI unveiled two new solutions for the packaging industry at drupa: The Packsize® EFI™ X5® Nozomi for the corrugated packaging industry prints, cuts, creases, glues, and reportedly erects customized boxes at rates of one box every six seconds with high-resolution graphics.

In other packaging news, EFI announced the EFI Nozomi 14000 AQ, a water-based, single-pass inkjet technology for corrugated packaging and displays. The company says that they offer packaging producers another choice for their corrugated applications and are compliant with the European Printing Ink Association (EuPIA), Swiss Ordinance RS817.023.21, and Nestlé Guidance Note & European directives on packaging inks.

Furthermore, EFI announced the EFI Nozomi 12000 MP single-pass LED inkjet technology for direct-to-metal printing, specifically designed for printing on metal, aluminium, and tinplate packaging.

Screen Europe

Screen Europe has chosen the theme of “Creating a Future in Print – Tech x Irodori” to offer visitors insights into the transformative impact of industry cooperation on the future of printing.

The Packaging Europe team visited Screen Europe and spoke to the company’s Business Development Director for Flexible Packaging, Juan Cano, about the new Truepress PAC 830F for plastic films as well as the Truepress PAC 520P which is suitable for printing on paper packaging.

Watch the video here:

ATS Tanner

Finally, we also stopped by the ATS Tanner stand and spoke with Head of International Sales, Urs Fischer, presenting the US-3000 banding machine which he says boasts user-friendly HMI, maintenance accessibility, and reliability.

Watch the video here:

The next drupa will be held in 2028, but no exact dates have been announced yet.

No comments yet