Domino Printing Sciences has announced the launch of the K600G – a new blister foil and web digital printing solution for product-level serialisation in pharmaceutical applications.

The solution has been developed in collaboration with pharmaceutical industry innovator Gallarus, and with engagement from life science industry experts SeaVision

“Over the last couple of years serialisation at the pack level has become a global requirement in the pharmaceutical industry,” says Craig Stobie, director of global sector development at Domino. “In the future, it is likely that serialisation of individual pockets of a blister pack will become the new standard, in order to further enhance patient safety and reduce medical errors.

“The K600G has been developed to provide manufacturers with an on-site solution for variable data printing, which includes coding at the item level, to meet these future requirements,” he continues.

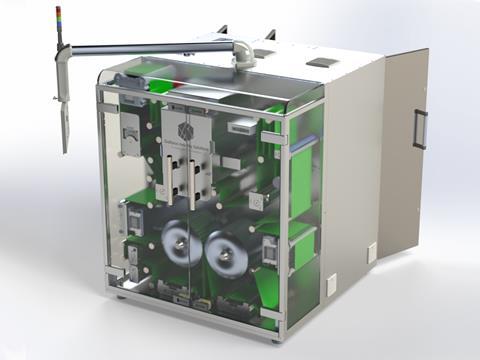

The new K600G includes a range of solutions that have been developed for different installation types, including off-line, near-line, top-of-line, sealed-blister-coding for printing directly on formed blister packs, and an integrated-line version developed to meet the needs of OEMs.

“Digital printing and flexible supply chains are beginning to play a much greater role in pharmaceutical manufacturing – and so the K600G is a necessary investment to keep up with future legislation and market trends,” says Volker Watzke, EU medical devices sector manager at Domino.

When it comes to printing performance, Domino says that the K600G achieves high-quality, reliable printing across a range of substrates – the printing module has a native resolution of 600dpi and excellent greyscale capability.

Based on Domino’s piezo drop-on-demand inkjet technology, the printer is also capable of building up imagery using multiple different drop sizes – a feature that, according to the company, improves image quality and gives manufacturers more control over their ink consumption.

The company also says that, in order to achieve the highest levels of efficiency, the system can also be supplied with a unique AI software that collects, analyses, and learns from factory data to provide intelligent manufacturing solutions.

The K600G is reportedly capable of printing at speeds of up to 75 metres per minute and print widths range from a single print module, covering 108mm (4.25”), up to seven dual print modules with a combined width of 782mm (30.81”).