In the first of two articles, Uli Merkle, head of marketing services at Busch Dienste GmbH in Germany, explores the benefits of vacuum technology in the food packaging industry.

Minimizing costs while working in a manner that is as environmentally friendly as possible – these are basic requirements for every production today. Energy consumption always plays a key role in the cost-effective/environmental balance. This is particularly the case when ISO 50001 certification of energy management is planned or required. The more efficiently the input energy is used, the sooner the specified basic requirements are met.

Vacuum technology is increasingly being used in numerous industrial food processing and packaging processes, whose energy efficiency has a corresponding effect on the overall energy balance of the company. This two-part article provides an overview of energy consumption and savings potential in vacuum supply. The first part discusses the basics of vacuum generation. The second part considers the application of vacuum technology in food packaging with chamber, thermoforming and tray sealer packaging machines.

Efficient energy management includes the planning and operation of the installation. In vacuum applications, both the generation and consumption side have to be considered. The specific machine technology offers various possibilities for saving on resources and costs, as well as contributing to the protection of the environment. At the same time, the focus must not be narrowed down to the energy consumption of the individual machines. Only a holistic view of the numerous factors that influence the overall efficiency will reveal possible synergies.

These factors include:

• Planning and installation overhead

• Service life

• Uptime

• Operating and training overhead

• Support from the manufacturer/supplier

• Expandability

• Servicing overhead, including downtime

• Operating fluids

• Disposal

The life cycle costs are the sum of these factors (cost of ownership).

Vacuum generation

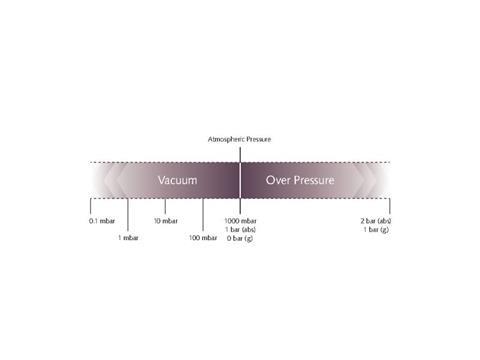

In general, "vacuum" means a negative pressure that is lower than theprevailing atmospheric pressure (Fig. 1). When describing the different vacuum levels, the paradoxical peculiarities of specialist language can confuse laymen: the lower the pressure, the higher the vacuum.

There are three basic parameters for selecting a vacuum pump. Of course,these also apply to the assessment of an existing system:

• Ultimate pressure [mbar]

• Pumping speed [m3/h]

• Nominal motor rating [kW]

Ultimate pressure [mbar]

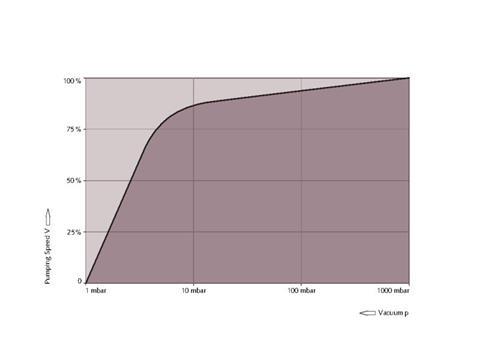

The ultimate pressure is the lowest pressure or the highest vacuum level that the vacuum pump can reach. When the ultimate pressure is reached, the pumping speed drops to zero (Fig. 2). The ultimate pressure, like all other pressures in the vacuum range, is specified in millibar [mbar]. The pascal [Pa] or hectopascal [hPa] units of the international SI standard system have so far not been accepted in most industrial processes (1 mbar = 1 hPa).

Pumping speed [m3/h]

The nominal pumping speed of a vacuum pump indicates how much air or gas it can pump down at atmospheric pressure over a certain period of time. Cubic meters per hour [m3/h] is the standard unit for this. The actual pumping speed decreases as the pressure decreases (Fig. 2). The pressure curve is represented by the pumping speed curve. It shows the actual pumping speed in all pressure ranges between atmospheric pressure and ultimate pressure. In the example shown of a pumping speed curve, the vacuum pump only achieves about 75 percent of the original pumping speed at an assumed negative pressure of 5 mbar in the packaging.

The course of this curve also influences the evacuation time and thus, for example, the duration of the packaging cycle for vacuum packaging. For this reason, it is necessary to determine exactly which size of vacuum pump makes sense to use when designing it. As a result, the desired negative pressure is achieved as efficiently as possible in the packaging process when packing in a specific chamber size and a specified cycle time. See "Design of the vacuum supply" for more information on this.

Nominal motor rating [kW]

The nominal motor rating is the output in kilowatts [kW] that is delivered to the motor shaft at rated voltage and current. The nominal motor rating is a maximum valuethat is not always called up in practice. The electrical energy actually absorbed is calculated from the real output shaft power and the efficiency of the motor (Fig. 3).

For some motor or vacuum pump manufacturers, the nominal motor rating is specified in conjunction with the service factor (S.F.). The actual maximum motor power is calculated by multiplying the nominal motor rating by the service factor. It is correspondingly higher than the kW value alone suggests.

The service factor (S.F.) was defined as standard by the US National Electrical Manufacturers Association (NEMA) in the NEMA MG1-2011 manual. It is indicated on thetype plate as a multiplier and describes the degree to which a motor can be loaded beyond the nominal motor rating. To do this, multiply the nominal motor ratingby the S.F. value. A nominal motor rating of 15.0 kW and a S.F. of 1.25 result in the maximum permissible nominal motor rating of 15 x 1.25 = 18.75 kW. The actual maximum rated power is therefore 25 percent higher than the "nominal motor rating" value.

Design of the vacuum supply

The vacuum pumps are usually designed by the manufacturer of the packaging machine who uses corresponding empirical values for this purpose. Their performance is geared to the greatest possible packaging capacity in terms of product quantity, chamber volume and machine cycle times. In turn, this means that if the packaging capacity is not fully utilized, the vacuum pump is oversized and therefore consumes more energy than necessary.

In principle, it is possible and often sensible to install more than just one vacuum pump designed for the maximum required pumping speed. Different productsare often packaged on the same packaging machine at different times. Size, packaging volume and cycle time may vary considerably. In such cases it is often worthwhile to connect two or three smaller vacuum pumps in parallel. The vacuum pumps can be controlled in such a way that only those vacuum pumps are in operation that are really needed to provide the required pumping speed. In order to shorten the cycle time, a multiple-stage vacuum system can also be much more efficient than a single larger vacuum pump.

Another highly efficient method for vacuum generation is the combination of a rotary vane vacuum pump with a vacuum booster (Fig. 3).A vacuum booster significantly increases the performance of the rotary vane vacuum pump. The right combination of a rotary vane vacuum pump (backing pump) and a vacuum booster allows for a high pumping speed which could otherwise only be achieved with a considerably larger individual vacuum pump – with correspondingly higher energy consumption. The results are shorter cycle times and considerable energy savings.

Summary

The energy consumption data should be carefully considered when selecting the vacuum pump. In addition, the size of the vacuum pump has to be adapted to the actual requirements. Possible alternative vacuum pump combinations must be considered for different packaging capacities. It is generally a good idea to consult a vacuum specialist with the necessary experience in the field of vacuum packaging who has an extensive product range of different vacuum generators.

More info: