Despite initial optimism for gasification, one of the primary methods of chemically recycling plastics, the industry has faced major setbacks in 2024. With over 90% of capacity offline in some places, and future projects dwindling, the sector stands at a pivotal crossroads.

In this analysis, Joshua Dill, Plastics Recycling Analyst at ICIS, examines the critical challenges of strict regulations, technical issues, and high financial risks that are stalling gasification projects.

The gasification of mixed waste, including plastics and non-plastics, has consistently faced various challenges.

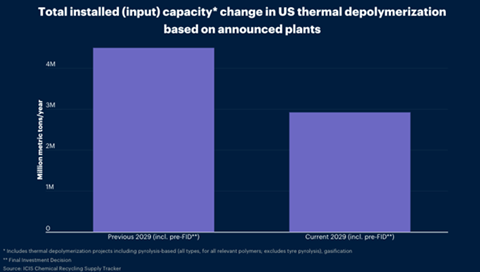

The end of 2022 was a significant confidence booster for the industry as another large-scale facility came online in North America. However, that confidence has been muted in 2024, as over 90% of the operating 2024 capacity for gasification in North America has gone offline, and future capacity has also been taken out of the announced pipeline. Below is a graph comparing the announced capacity for 2029 before and after the changes in gasification were taken into account.

While there are many reasons for the gasification closures, the primary factors can be divided into three categories: legislative, technical, and economic.

On the legislative front, gasification facilities face strict permitting rules. These rules can be especially stringent in states where chemical recycling has not been adopted into law, as was the case with some of the capacity that was taken offline.

Additionally, especially when a facility is in its initial stages, it will face high levels of scrutiny from both the state government and the public, particularly regarding worker and environmental safety. As a result, the facility may be required to update its permits. A consequence of permit updates is unexpected shutdowns, bringing production to a temporary halt.

As it takes time to perfect the technical process, newer facilities often face challenges which again can cause downtime. A common technical challenge among gasification-based chemical recyclers is clogging.

This can be defined as an obstruction in the planned flow of material through the plant. While prevalent for other types of recycling as well, clogging can be exacerbated in gasification facilities due to their larger size. Clogging yields a similar outcome to permitting, causing temporary shutdowns and bringing production to a halt.

Gasification-based chemical recycling facilities are costly, making borrowing a common project financing option. Due to the size of the investments, creditors often set deadlines for the company to begin producing outputs. Consequently, any production halt - whether caused by legislative or technical issues - can severely threaten the long-term viability of the facility.

Overall, many of the existing gasification facilities were not able to overcome the common pitfalls faced by the chemical recycling industry. Until the industry is able to overcome the mentioned barriers, it might be a while before a new wave of gasification facilities is on the horizon.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet