Colour Tone, (stand A009), PDM 2018, 19th-20th June 2018, is urging producers and retailers to look beyond the removal of carbon black pigments if they are to help optimise the detection and sorting of non-clear plastics packaging for recycling.

Colour Tone’s Director, Tony Gaukroger will be delivering a presentation as part of the show’s sustainability programme, ‘Designing for ‘end of life’ – finding a solution for non-clear plastic packaging waste’ at 11.40pm on Wednesday 20th June 2018.

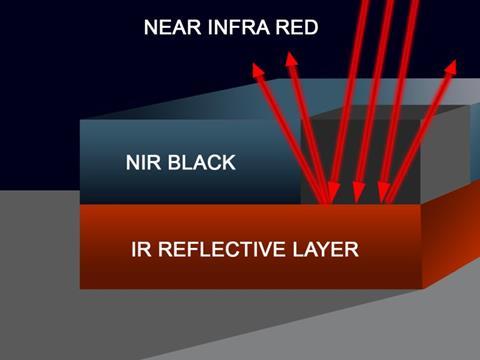

Tony Gaukroger, Colour Tone director, explains: “A belief has persisted for some time now that carbon black pigments alone prevent the detection of non-clear (black and coloured) plastics packaging via near-infrared (NIR) optical sorting methods used by recyclers.

“Carbon black pigment is an extremely efficient absorber of infrared, but if you remove it from a colour it does not necessarily solve inherent optical detection problems. Since all coloured pigments have their own individual characteristics or infrared ‘footprints’ with varying degrees of infrared absorption, the combination of these too can inhibit the ability to NIR sort.

“The blending of pigments presents therefore a complex challenge, as different material system variations may contribute to differing reflectance levels in the near-infrared range. So when you mix different pigments together their attributes can in some instances significantly decline as their signature may cancel out others reflectance levels.”

In response Luxus subsidiary Colour Tone has recently launched a rapid coloured polymer analysis service that tests for ‘end-of-life’ recyclability of non-clear packaging. It enables producers to discover if their plastics packaging can be detected via near-infrared (NIR) sorting.

This service enables produces and retailers to quickly assess if any coloured plastic item produced offers an indicative view of whether it can be detected and if not, it will provide a colour matched infrared detectable alternative based on its colourant technology.

A new spectrophotometer is supporting this service which is capable of reading solar reflectance in the near-infrared spectrum. It enables the measurement of reflectance levels by generating graphical displays of each individual colourant wavelengths to ensure that specified polymers do not inhibit near-infrared sorting.

According to the company,This service represents a real ‘game changer’ as it is the only one where a spectrophotometer is being used to identify near-infrared reflectance levels to achieve the very best NIR sorting wavelengths for plastics that previously would have remained undetected ending up in landfill.

It can clearly identify pigment mixes given a near-infrared footprint and then expertly assess every possible colourant combination to meet the challenge of finding the closest and most economically viable colour match for brand owners to satisfy both aesthetic and eco-concerns.

More info: