With the launch of its FlexBuffer application cell, ABB hopes to respond to growing consumer demand for choice, flexibility, and fast delivery.

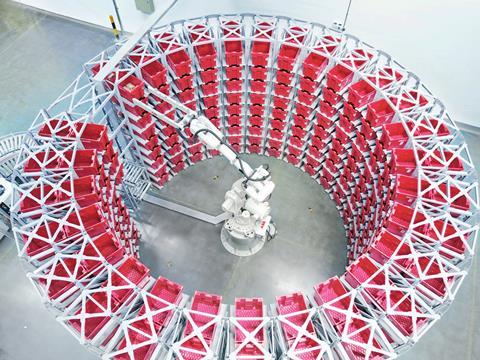

Comprising of an ABB robot, a suite of grippers, a software package, storage racking, and infeed and outfeed conveyors that feed and dispatch goods, FlexBuffer is a multi-functional solution made for processing a variety of customer orders.

Incoming orders are managed by software that interfaces with WMS, ERP and AMS systems. The software suite manages the storage and retrieval of mixed items, apparently avoiding collisions and optimizing storage use.

Information from the software is used by the robot to store goods in the appropriate rack positions, based on the sequence in which they need to be dispatched. When objects need to be retrieved, the robot can select the requested goods in sequence and place them on the outbound conveyor, ready for dispatch.

Marc Segura, group senior vice president and managing director for consumer segments and service robotics at ABB, comments: “The constantly changing nature of today’s consumer landscape and the explosion of e-commerce is challenging the conventional systems used for processing and delivering orders. The FlexBuffer helps our customers meet these challenges by bringing automated storage and retrieval and goods sequencing to all facilities.

“Now, any size operation, from large stores to small pharmacies can achieve maximum efficiency in handling a wide range of items. With FlexBuffer, our customers will have the flexibility to store and retrieve goods as they want, in any sequence to suit their operation and customers’ needs, as well as the ability to quickly scale up their operations if required.”

Currently, active pilot installations include a pharmaceuticals storage and bin-picking application at the Shanghai 7th Hospital in China, an automatic retail store for Chinese mobile communications company Huawei that allows customers to collect their mobile phone orders via an automated booth, and an order picking system for British retailer, John Lewis & Partners.