Ruben Rausing, the founder of Tetra Pak, once said that “packaging should save more than it costs.” Valeriy Krivoshey, Ph.D., editor-in-chief of Packaging Magazine, tells us what companies – and consumers – should bear in mind when thinking about the cost of packaging.

When buying a product, the average consumer never knows how much the package costs for them. Most likely, they hardly think about it. Although one liter of milk in a polymer bottle, a package of three-layer polymer film, and a pack of tetra packs made of a composite material based on cardboard all have a different cost.

Even more, they have no idea that the cost of a single two-liter bottle of polyethylene terephthalate for mineral water is less than four 0.5 liter bottles of the same material for the same amount of the same water. And at the same time, they will buy water in bottles of 0.5 liters, despite the fact that they will overpay.

Any packaging made of any material for any product has its value. It is primarily important for the manufacturer of products, and secondly - for the business that sells these products. And only in third place is the consumer, although today they are the main person in the market, because their purchases set requirements for both products and packaging.

The cost of any package, as well as any other product, consists of cost and a certain profit. Its price also depends on the value and cost of the product itself. Therefore, the same cost of packaging (eg, cardboard) for chocolates, perfumes and bank VIP cards can vary in price several times, ranging from 5 to 30-40% of the cost of the product itself.

Of course, the price of packaging depends on material and energy costs, the cost of human labor, technology and equipment used, the cost of logistics, advertising, etc. In addition, in most cases, it depends on competition in a particular packaging market.

Commenting on all the metamorphoses with the price of a package, in my opinion, we must remember the words of Ruben Rausing, founder of Tetra Pak: “Packaging should save more than it costs.” And this is the transition to another category of reflection.

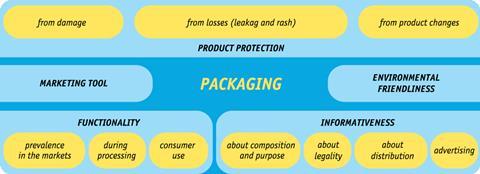

It should be noted that the price of packaging is primarily related to the functions that are assigned to it. It is difficult to determine the share that each of them contributes to the price of packaging. Probably, for different types of products, they are different. But such a connection between the price of packaging and its functions is easier for consumers to understand.

After all, it is the consumer who determines how important each packaging function is to them for the products they buy. In addition, the consumer’s purchases form requirements for packaging through its functions and thus indirectly affect the price of products. Providing each of these functions of packaging requires certain costs in its development, production and distribution.

Fig. 1.The main functions of packaging

In my opinion, among these functions, for the consumer, the most important are product protection, information and functionality (convenience). Let’s focus on protecting products from spoilage and damage, losses from leaks and spills, from changes in the product itself.

Apparently, the provision of this packaging function is the most expensive, because it is associated with the type of packaging material, the design of the packaging, technology and equipment for their production, which requires the highest material and energy costs. They make up the largest share in the cost of packaging.

In addition, it should be noted that when this packaging function “does not work”, the packaged products are spoiled and discarded. Suffice it to say that due to poor packaging, humanity loses 1/3 of food every year, which is 1.3 billion tons worth more than $ 250 million.

Packaging of different designs, form sizes and types of packing materials (paper, cardboard, polymers, glass, metal, wood, others) is used. Its development or selection depends on the type and product properties as well as its storage requirements.

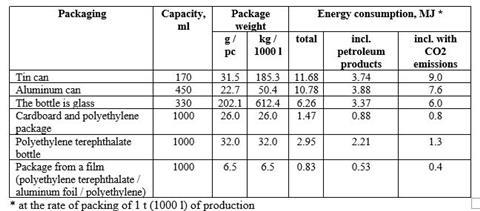

To understand how the cost of packaging is affected by the above factors, consider the cost of producing different types of packaging for the same product (table).

Table: material and energy costs for the production of packaging *

The order of arrangement of packaging from different materials for packaging the same amount of products in ascending order of the cost of material for the manufacture of packaging is shown in Fig. 2a (from the package of film to the glass bottle), and the cost of energy resources - in Fig. 2b (from a package of film to cans of tin).

In addition, the use of glass and metal packaging is associated with increased transport costs. It is also an additional fuel, increasing emissions of harmful gases into the air. Packaging of these materials is the most energy-consuming.

Cardboard with polymer layers packaging is not so safe for the environment. Although its energy consumption is lower than that of glass and metal packaging, water and energy are used more than plastic packaging, and the environment is polluted on a larger scale, especially with wastewater.

There are several general conditions, without which it is almost impossible to make significant progress towards reducing the cost of packaging materials and packaging. First, any packaging, if it is safe for humans and the environment, is used for the packing of specific products.

Second, the evaluation of the properties, advantages and disadvantages of packaging must take into account its entire life cycle, and this approach should be used when designing, selecting or selecting packaging for a particular product. Third, a comprehensive approach based on reasonable and objective trade-offs is needed in the development of packaging with the participation of manufacturers of materials, packaging, packaging products and trade. Finally, it is necessary to understand that the used packaging from any packaging materials is a useful secondary raw material.

Based on these conditions, as well as taking into account the current requirements of the consumer to packaging, which is their satisfaction with the full implementation of the functions of packaging, the packaging industry plans and implements its strategic development plans. There has long been a competitive change in the structure of packaging for packaging materials towards the use of lighter, lower-cost soft and rigid polymer packaging - both consumer and group and transport based on heat-shrinkable and stretch films.

Packaging made of paper and cardboard is still very popular. Pack, which has also reduced its weight, and due to the use of new types of cardboard and corrugated cardboard - and its cost. Many glass industry companies use Narrow Neck Press and Blow (NNPB) technology, which allows manufacturers to reduce the weight of the bottle and control the thickness of the walls over the entire plane of the bottle.

Along with weight, the costs of raw materials, energy and transportation are also reduced. Manufacturers of tin and aluminium containers have reduced by 15-20% both the thickness of the tin and the weight of cans made of it. Leading companies are looking for new designs and shapes of cans, which leads to a reduction in their weight, and have mastered the technology of continuous drawing of cans using different coatings, which also leads to a reduction in the weight of tin packaging.

Finally, the last commitments of packers are aimed at more economical use of packaging through its reuse, recycling of packaging waste for secondary resources or energy. The consumer must join this common cause, not only by fulfilling the postulates of the packaging waste management system, but also by optimizing their needs for food, beverages and industrial products, which will reduce their losses due to spoilage and damage.

No comments yet