Walki's combined folding box concept with a special tear-off strip embedded in the cardboard and an intelligent folding mechanism for re-sealing was designed to answer demands for both efficiency and sustainability. Originally developed for packaging fish fingers, the innovation can be used for a wide variety of products thanks to the barrier coatings specially adapted to the product.

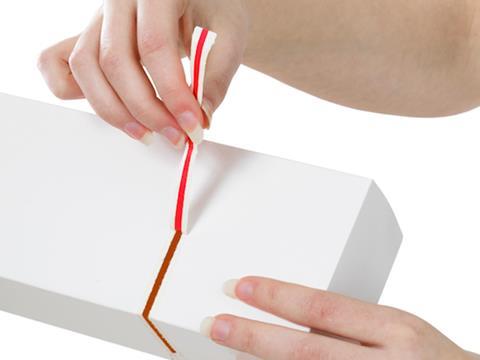

The tear-off strip Walki-Tear-Strip is not punched out of the cardboard through perforation in the usual way, but embedded in it. Walki says this embedding process is a complex one, as the polyethylene strip must be stable enough to open the packaging reliably, but thin enough that it does not impede production.

“The tear takes place so accurately and cleanly that no cardboard fibres come loose and enter the product,” explains Stefan Erdmann, Technical Service & Development Manager Barrier Board at Walki. “Because the Walki-Tear-Strip uses no perforations, the barrier surface remains completely intact, which guarantees safety. The visual appearance of the imprint and finish is also not interrupted.”

Intelligent mechanism for ease of use

Two packaging sections are created when opening with the tear strip, which can be sealed again easily by folding at the side and inserting the sections into each other.

“The mechanism is easy to understand. In practice, we have noticed that the consumers identify the slight grooves on the sides of the packaging instantly as a folding point, which enables the two packaging sections to be inserted into each other when actuated”, confirms Erdmann. “This saves resources, as the consumers no longer re-package the products into plastic bags, for example, to keep everything in an orderly fashion, but can simply leave them in the sealed packaging.”

Sustainability and versatility

With cardboard as a renewable and recyclable base material, Walki says the packaging has a high sustainability value. The re-sealing feature means that it can be re-used multiple times, which saves resources and helps to prevent waste. As a secure primary packaging with no additional shell, Walki-Pack also reduces the packaging quantity for the benefit of the environment and costs.

“Whether frozen foods, fresh produce or dry goods like cereals, salt or animal foods, right through to household goods and pharmaceuticals – the concept can be used for practically any product thanks to the barrier coatings individually adapted to the product”, explains Erdmann. “The solutions provide protection from water, water vapour, grease or aroma diffusion, for example.”