Mamen Moreno Lerma, food contact and packaging group leader at AIMPLAS, talks about the ins and outs of ensuring cosmetics packaging is safe.

People are becoming increasingly more demanding when acquiring new products, as demonstrated by the work being done by the competent authorities, the cosmetics industry, packaging manufacturers and industry associations.

When we speak about safety of cosmetic packaging, we must have in mind current legislation and in this regard, within the European framework we have Regulation 1223/2009 on cosmetic products. According to Annex I of the Regulation, the Cosmetic Product Safety Report must include details on impurities, traces and information about the packaging material, including the purity of substances and mixtures, evidence of their technical unavoidability in the case of traces of prohibited substances, and the relevant characteristics of packaging material, in particular purity and stability.

Other legislation includes Decision 2013/674/EU, which establishes guidelines to make it easier for companies to meet the requirements of Annex I of Regulation (EC) No. 1223/2009. This Decision specifies the information that should be collected on the packaging material and potential migration of substances from the packaging to the cosmetic product.

In June 2019, Cosmetics Europe published a non-legally binding document, the aim of which is to support and facilitate assessment of the impact of packaging on product safety when the cosmetic product is in direct contact with the packaging.

Packaging in direct contact with the cosmetic product is called primary packaging. The characteristics of the materials in direct contact with the product are therefore important in terms of cosmetic product safety. Information on the characteristics of these packaging materials should make it possible to estimate any potential risks. Relevant characteristics can include the composition of the packaging material, including technical substances such as additives, technically unavoidable impurities or substance migration from the packaging.

Because the greatest concern is the possible migration of substances from the packaging to the cosmetic product and that no standard procedures are available in this area, one of the industry’s most widely established and accepted methodologies is based on verifying compliance with food contact legislation.

The materials used to manufacture cosmetic product packaging include plastics, adhesives, metals, alloys, paper, cardboard, printing inks, varnishes, rubber, silicones, glass and ceramics. In accordance with the regulatory framework for food contact, these materials and articles are regulated by Regulation 1935/2004, which is known as the Framework Regulation. These materials and articles should also be manufactured in accordance with good manufacturing practice (GMP), based on systems for quality assurance, quality control and documentation. This requirement is described in Regulation 2023/2006(5).The Framework Regulation also provides for the possibility of establishing specific measures for each type of material to ensure compliance with the basic principles established. The material for which the most specific measures have been established is plastic, as covered by Regulation 10/2011(6) and subsequent amendments.

Regulation 10/2011 establishes the requirements to be complied with regarding raw materials and finished products. The information to be included in the Declaration of Compliance is listed in Annex IV (this annex is complemented by the Union Guidance as regards information in the supply chain. The Union Guidance aims to provide key information on the transmission of information required to comply with Regulation 10/2011 in the supply chain). Regulation 10/2011 also sets out quantitative restrictions on substances that can be present in the final product or can be released into food (migration) and lays down the standards for testing and migration test results (a requirement of final products).

In terms of laboratory analysis, to verify compliance with the specific migration limits set out in Regulation 10/2011, the laboratory steps to be taken include:

1. The packaging manufacturer must have the Declaration of Compliance (DoC) for all plastic raw materials used, based on Annex IV of Regulation 10/2011. This supporting document enables users to check if a material is formulated for food contact, i.e. if all the substances used in the formulation are listed (except for justified exceptions) in Annex I and II of Regulation 10/2011 and subsequent amendments.

2. Carrying out overall migration tests with the aim of verifying the inertness of a material (if applicable). In overall migration, the total amount of non-volatile substances that can migrate into the food is quantified without identifying the individual substances. Overall migration tests are carried out in accordance with standard UNE EN-1186. These tests with the simulant vary in number and form of contact (e.g. immersion, one-sided contact, filling).The overall migration limit is 10 mg/dm2 of contact surface area. For plastic materials in contact with food for breast-feeding infants and young children, the limit is 60 mg/kg of food simulant.

3. If necessary, carrying out quantification tests on the residual content and/or specific migration with the aim of verifying compliance with the limits set out in legislation for each substance.

Specific migration tests are carried out in accordance with the UNE-CEN/TS 13130 standard series, along with internal testing procedures developed in laboratories for chromatographic analysis.After reviewing the DoC, a decision is taken as to whether it is necessary to perform this kind of testing.Of all permitted substances, only some have restrictions and/or specifications. The ones with specifications must be listed in the DoC to allow for verification of compliance with the corresponding limits in the material or final article.The units used to express residual content results are mg of the substance per kg of final product, whereas the units used to express specific migration results are mg of the substance per kg of simulant.

To design the overall and specific migration tests, the simulants and exposure conditions must be selected.

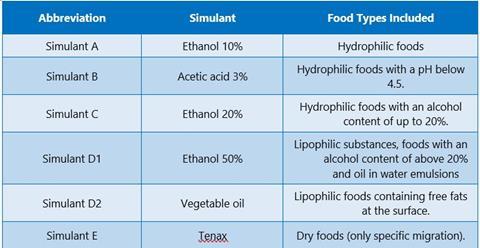

• Simulants: Based on the foods/cosmetics that can make contact with the material, test simulants are selected as per the directives included in Annex III of Regulation 10/2011.

When carrying out migration tests on cosmetic product packaging, it is necessary to consider the simulants to be selected. Cosmetics are usually chemically inert water/oil-based mixtures with a neutral or slightly acidic pH. For most cosmetic formulations, the physical and chemical properties relevant for migration correspond to the properties of the foodstuffs described above. Therefore, an approach like the one taken with foodstuffs can be adopted. However, some alkaline preparations such as haircare products cannot be represented by the simulants mentioned.

• Exposure conditions:

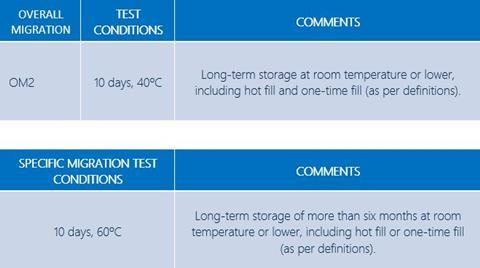

To select the exposure conditions, the time and temperature of contact between the packaging and the foodstuff/cosmetic from packaging until the expiry date should be considered. This ensures that test conditions representing the worst foreseeable conditions of actual use are selected. The conditions for overall and specific migration are selected separately. Sometimes, they are the same, but are described in different chapters of Regulation 10/2011.

The most common test conditions to be applied in a cosmetic packaging are:

Compliance with packaging legislation (after verification of all applicable restrictions) must be detailed in the relevant DoC, which must include information on the uses for which it is safe to bring the material or article into contact with foodstuffs/cosmetics (e.g. types of food, time and temperature of use). The DoC is then evaluated by the cosmetic product safety consultant.

Plastic packaging intended to be used with cosmetic products is not obliged to comply with Regulation 10/2011, but the most practical option is probably to adopt an approach like the one taken with foodstuffs and to assume during the packaging design process that the raw materials must be suitable for food contact. Only when all agents in the supply chain are involved in compliance with legislative requirements will it be possible to guarantee the safety of packaged products.