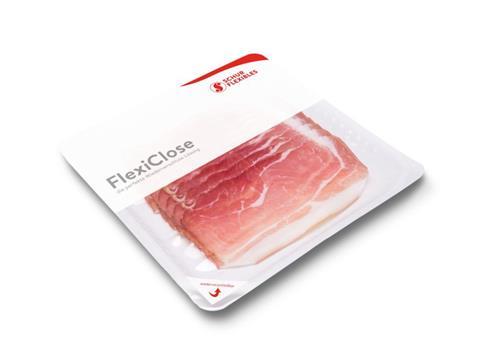

With the FlexiClose product range, Schur Flexibles offers flexible reclosing solutions for a wide range of markets and applications. Schur Flexibles' in-house-extruded sealing and functional layers can be tailored to customers´ requirements.

For instance the sealing against polyethylene or polyester films can be individually chosen as well as the level of the gas barrier. The excellent product presentation qualities through high transparency and perfect anti-fog properties characterise all FlexiClose reclosing films by Schur Flexibles, as well as a guaranteed machinability. The consumers´ requirements for easy opening packages and pack security is met by low opening forces and up to ten safely functioning re-sealing cycles. Therefore, Schur Flexibles' FlexiClose is ideally suited for the packaging of sliced food products such as cheese, cold meats or fish. The ideal film for the range of portion-packs for salads, bread spreads or cream cheese can also be found within the FlexiClose programme.

For thermoformed, preformed trays and flow pack applications

In addition to the FlexiClose T for PE based bottom film systems and FlexiClose TM for the sealing of PET based monofilms, Schur Flexibles also offers a solution for top forming applications (FlexiClose TF). The FlexiClose programme is completed by the FlexiClose FW. With this film the production of reclosable pouches on horizontal and vertical flow packing lines is possible without a costly retrofitting investment.

FlexiClose for more sustainability

Through the use of an innovative PET-sealing layer, the material share of the overall packaging can be reduced by up to 20 percent with FlexiClose film solutions – a real contribution to added sustainability in the packaging sector through a significant reduction in the CO2 footprint.

Printed in high quality, with special effects

The innovative FlexiClose materials can be printed in up to 10 colours, either using flexo or rotogravure printing. With a wide range of finishing options, through effects such as matt or gloss finishes and paperlike haptics, attractive packagings can be produced, which ensure that the product stands out for the customer at the POS.

More info: