At this year’s PackExpo in Chicago, Schubert will be presenting the advanced features of its Flowmodul flow-wrapping component. Thanks to a new, patented heat-sealing technology, heat-sensitive products can now be packaged even more gently in flow-wrap bags.

The Flowmodul layout on exhibit corresponds to the latest model variant, which stands out with its enhanced accessibility. Additionally, visitors to the fair will have an opportunity to learn about the high-level versatility of the robot tools the packaging machine manufacturer has developed. Precisely adapted to product-specific applications, they significantly contribute to the flexibility of the TLM machines. Schubert will also be informing visitors on the many advantages of its comprehensive service portfolio and web-based GRIPS.world customer platform, which ensures high plant availability.

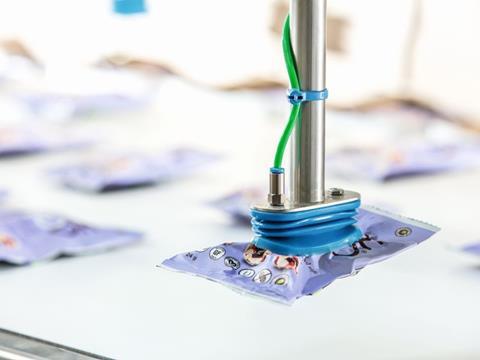

New sealing technology for the FlowmodulThe latest model variant of the Flowmodul flow-wrapping component features an even more open machine layout, which further facilitates accessibility for maintenance and cleaning. Additionally, Schubert now offers an even more extensive selection of possible sealing technologies. This enables customers to choose the most suitable processes for their products. For example, Schubert has developed a new heat-sealing technology specifically for highly sensitive products. In the case of hot-seal films, the Flowmodul adapts seamlessly to the variable speeds of the upstream F44 robots, without this having an effect on the seal quality or the tightness of the flow-wrap bags. The patented flying transverse sealing unit used here is highly flexible and ensures that the sealing times remain constant. If hermetically sealed packages are required, the sealing time can be set accordingly.

The machine exhibited at PackExpo is equipped with this new, quickly-adjusted heat-sealing technology. The exhibit will package mixpacks with two different products – one biscuit each with white chocolate and one with brown chocolate. The machine achieves an output of 250 products or 125 flow-wrap bags per minute. Alternatively, the flow-wrapping machine can be provided with a non-rotating ultrasonic longitudinal sealing unit, which is especially suitable for films with high barrier effect. Both systems are characterised by low heat development, which makes them ideally suited for heat-sensitive products such as chocolate.

With the Flowmodul, Schubert offers a flow-wrapping component with which the packaging of products in flow-wrap bags can be fully integrated into the packaging machine manufacturer’s modular machine concept. Thanks to the uniform machine control of the TLM system and the flow-wrapping component, operation is user-friendly. The flow-wrapping component can be operated together with the entire line via a single HMI interface. The Flowmodul is supplemented by standard Schubert components such as the image recognition system, which ensures that only perfect products enter the feed chain. If the product needs to be placed in a carton or plastic tray, this function can be easily implemented with an additional sub-machine.

Product-specific robot toolsAnother focus for Schubert at the trade fair will be on the robotic tools it develops and manufactures. The exceptional modularity of the TLM technology makes it easy to use a TLM system to adapt to future requirements: when changing products and formats, only the robot tools need to be adapted or exchanged. Schubert looks back on many years of expertise in the design and functionality of grippers and suction cups. Since 2014, the company has also relied on the use of 3D printing technology for producing its tools. With additive manufacturing, the company can produce robot tools with previously impossible functions and features. As part of the Schubert service package, the company also provides tools for new applications.

The service and digitalisation strategyTo ensure that both new and existing customers can quickly reach the right contact for their inquiries, the Schubert Group offers a comprehensive range of services consisting of five pillars. These service modules are backed by a highly qualified team of experts who support customers worldwide throughout the entire lifecycle of the TLM machine.

The company is focused on the goal of entirely avoiding downtime and unplanned service assignments in the future. Schubert is committed to offering customers preventive service and, with this in mind, it relies on digitalisation and close networking. As part of Schubert’s service strategy, all TLM machines can be connected with the GRIPS.world digital platform via the Internet. Through predictive maintenance, this platform ensures long-term investment security in a TLM system. Furthermore, in the future, customers will benefit from the integrated condition monitoring of information and data, which will helps them further increase their productivity. The packaging machine manufacturer guarantees secure data transfer through the GS.Gate. This machine gateway, developed by subsidiary Schubert System Elektronik in cooperation with genua GmbH, protects the data via a firewall, which encrypts it with high-level security.