Integrated packaging solutions leader Pro Mach, Inc. has announced it has acquired global high-speed labeling solutions provider P.E. Labellers SpA. The addition of Italy-based P.E. Labellers expands Pro Mach’s capabilities to provide high-speed decorative labeling and integrated solutions worldwide. All global subsidiaries and management teams of P.E. Labellers join the Pro Mach team.

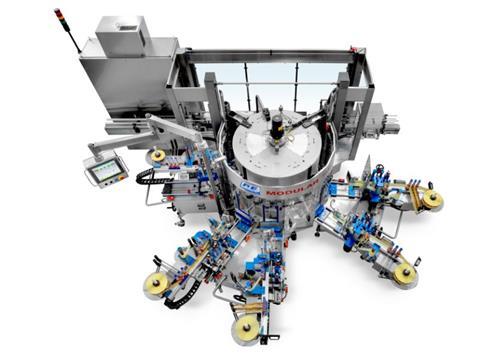

P.E. Labellers has been a technology leader in automatic high-speed rotary and linear labeling equipment for more than 40 years and provides a wide range of innovative labelers and solutions for consumer and industrial packaged goods companies from more than 10 facilities worldwide. P.E. Labellers’ solutions are completely modular and include self-adhesive, hot melt, cold glue, roll-fed, and sleeve labeling technologies. Full modularity and a universal machine body give users flexibility to easily install and swap different labeling systems depending on need and production environment. P.E. Labellers’ innovative ADHESLEEVE technology, which uses pre-glued films, has received industry-wide acclaim for its reliability, efficiency, sanitary design, and overall environmental friendliness, as well as reduction of costs and downtime. P.E. Labellers has more than 10,000 rotary and linear labelers installed worldwide.

“We’re pleased to welcome P.E. Labellers founder Bruno Negri and his global team to Pro Mach,” says Mark Anderson, Pro Mach President and CEO. “With the addition of P.E. Labellers, Pro Mach now has a very complete labeling solutions portfolio for almost any customer. Along with our other industry leading brands NJM Packaging, Weiler Labeling Systems, Axon, EPI Labelers, and ID Technology we now have a full-range of primary, secondary, and tertiary labeling solutions for virtually any application, including high-speed production lines, custom packaging, e-commerce, and complex pharmaceutical requirements.”

Bruno Negri, co-founder and Chairman of the Board of P.E. Labellers, along with Nicola Schinelli, Vice Chairman of P.E. Labellers, will continue to lead the P.E. Labellers team, spanning over 400 employees across the world.

“Pro Mach and P.E. Labellers bring together a great deal of experience and success in complementary and diverse markets,” says Mr. Negri. “Together we have many outstanding opportunities to better serve our mutual customers and introduce new ones to some of the packaging industry’s most innovative solutions across the entire packaging line. We remain fully committed to providing the global marketplace with the best labeling technology and customer support and I firmly believe with Pro Mach we have the ideal partner to help us continue our tremendous growth. We share a common strategic vision for the long-term future and will be adding new facilities to help us continue our focus and commitment to actively improving our already exceptional quality and service. I very much look forward to continuing to lead the P.E. Labellers team as we enter the next chapter of our story.”

Pro Mach has grown rapidly into a leading single-source provider of high-performance packaging lines and integrated solutions. It continues to add complementary packaging and processing machinery solutions and engineering services to advance its integrated systems capabilities worldwide. Since 2010, Pro Mach’s installed base of machinery solutions has more than doubled and sales outside of the United States have more than tripled. Pro Mach supports a global customer base with operations in North America, Europe, Middle East, and Asia. With more than 30 equipment brands sold around the world, Pro Mach continues to look at opportunities in global markets to strengthen its position as the preferred supplier of complete high-performance packaging lines.

“Many of our global customers want a single source provider of machinery solutions and integrated systems that will help them simplify line development, achieve optimum performance, reduce risks, and better manage costs,” says Barry Heiser, Pro Mach President, Global Filler and Integrated Solutions. “The core keystone systems that many of our high production customers want to integrate first are filling, capping, and labeling. The addition of P.E. Labellers advances our high-speed capabilities and helps us better serve these customers worldwide.”

More info: