Vector-borne diseases, i.e. diseases that are transmitted via blood-feeding insects such as mosquitos, ticks and fleas, have been increasing dramatically in recent years, and international trade is an important factor.

Lola Gómez Jiménez, Packaging Group researcher and Converting Processing Expert, AIMPLAS, Plastics Technology Centre explores how the Bio-Vectors project tackles the problem of making packaging both insect repellant and food safe.

Vector-borne diseases have been increasing at an alarming rate in the last 30 years, as stated in the article “Vector-transmitted diseases. A new challenge for public health surveillance systems”. They are caused by viruses, bacteria and parasites transmitted to humans via mosquitoes, Phlebotomine sandflies, triatomine bugs, ticks, tsetse flies, mites and lice. The main vector-borne human diseases include malaria, dengue fever, Chagas disease, leishmaniasis, chikungunya, Zika virus disease and yellow fever.

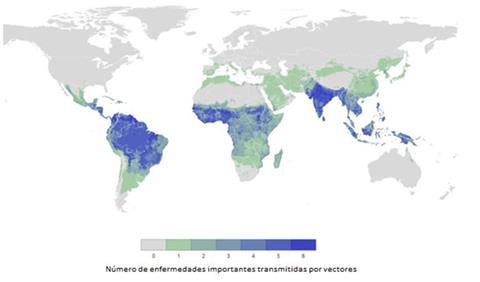

According to the World Health Organization (WHO), these diseases account for around 17% of all infectious diseases worldwide and cause more than 700,000 deaths each year. These diseases are primarily associated with Third World populations in tropical areas, but climate change on our planet has now enabled these pests to successfully spread to temperate regions. They are now a problem in many European populations and other economically developed regions, as shown in Figure 1.

Another factor causing this displacement of vectors is international trade, which has increased considerably since the 1980s. According to the United Nations, global transport of goods is expected to grow by as much as 4.3% by 2050. For this reason, “controlling vectors at entry points is extremely important to prevent invasive species from gaining a foothold in local environments, and to prevent exports of local vector species to other countries” through freight transport by land, air and sea.

This is the case of Aedes albopictus, also known as the tiger mosquito. Originally from Asia, it has spread to Europe , the United States and Brazil since the 1980s. This is not an isolated case. It has become common to hear about the presence of other vector-borne diseases such as West Nile virus and leishmaniasis, as well as infestations of cottony mealybug and citrus greening insects.

Working on vector control

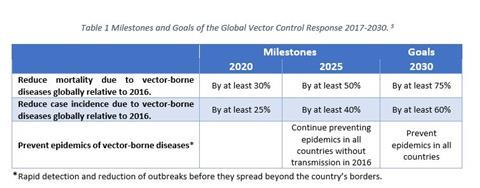

Drawing up a vector control programme to address the impact of vector-borne diseases is therefore urgent. The WHO has set in motion the Global Vector Control Response 2017-2030, which offers strategies that countries can follow for efficient, sustainable vector control with the aim of preventing disease and responding to outbreaks. The vector control goals outlined by the WHO, as well as the intermediate milestones for monitoring progress, are shown in Table 1.

As mentioned above, the increase in international trade is one of the causes of vector displacement. This problem includes the risks involved in transporting horticultural products and ornamental plants, which can carry insect eggs, larvae and adult insects.

The International Plant Protection Convention (IPPC) is working in this direction to develop international standards for handling plants and horticulture products in international trade. Wood packaging used in this kind of transport is a route for the introduction and spread of pests. For this reason, the IPPC issued standard ISPM 15, which indicates how wood packaging and pallets must be treated to eliminate such organisms. However, this standard does not address freight transport in cardboard packaging, and corrugated cardboard boxes are the most widely used in transport and distribution of this type of product. Paper is not very nutritious for most insects, but the other materials used to make boxes, such as adhesives (gelatines and starches), provide them with nutrition and facilitate the spread of insects. It is therefore necessary to find a treatment for cardboard packaging against vectors such as flies and mosquitoes.

Bio-Vectors Project

There is currently no specific treatment for these vector-borne diseases. One of the most effective solutions for preventing and controlling these epidemics is to take action against the vector itself (e.g. mosquito, fly), thus making preventive measures the best method of control.

There are now many repellent substances that are effective against these vectors. However, a number of these substances are not suitable for food contact and are also unstable at different temperatures: they break down easily during the manufacturing and application processes, which makes them difficult to use in many sectors.

The Bio-Vectors Project is tackling this problem and also addressing the need for treatment of cardboard packaging. To this end, work is underway to formulate a coating with insecticidal and repellent properties against flies and mosquitoes applied through flexographic printing to cardboard packaging. This coating will contain an active ingredient against insects to help reduce the spread of vectors in goods transport.

The project presents different challenges. First, the coating must be suitable for food contact and comply with Commission Regulation 10/2011 on plastic materials and articles intended to come into contact with food. This makes it necessary to carry out an exhaustive search for natural active ingredients that comply with this regulation and are also highly effective fly and mosquito repellents and insecticides. A micro-encapsulation process that can withstand high corrugated cardboard processing temperatures has also been developed to protect the active ingredients and overcome the challenge of thermolability. The resulting microcapsules prevent the premature release of the biocidal active ingredient. Moreover, release is controlled to achieve long-lasting functionalized materials. A preliminary process before devising the formula for the coating involved optimizing the dispersion process of the microcapsules in different resins to achieve homogeneous, stable dispersion and reach the maximum load concentration within the viscosity requirements of the methodology to be applied (flexographic printing). Finally, based on the dispersion testing carried out, it was possible to obtain water-based formulations with a low VOC content that are highly stable over time. The Bio-Vectors Project will finish at the end of 2020. In these last few months, the coatings’ insecticidal and repellent capacity will be evaluated, and migration testing will be performed to determine its suitability for food contact. The goal is to obtain a biocidal cardboard packaging demonstrator with a repellence index of 85%, a mortality rate of more than 80%, and controlled release of the active ingredient at six months.

AIMPLAS is a technology partner in the Bio-Vectors Project “Development of coatings with biocidal properties to prevent the spread of vectors in freight transport”. This project is being developed with three other companies (Laurentia, Pectro-Flexocolor and Smurfit Kappa) and has received funding from the Ministry of Science, Innovation and Universities under the Collaboration Challenges 2017 programme. This aid is co-financed by the European Union through ERDF funding with the aim of promoting technological development, innovation and quality research.