Container lids play a crucial role in preserving freshness, preventing contamination, and ensuring product integrity. Chris Hambley, a senior associate and patent attorney in the Advanced Engineering group at European IP firm, Withers & Rogers talks us through a patent for casein-based seals for food containers.

Traditionally, lids and seals for dry food and drink products, such as instant coffee jars, have relied on complex multi-layered structures, often involving plastics, metals, and adhesives. Whilst effective, these conventional solutions pose challenges for recycling, regulatory compliance, and sustainability.

Existing technologies for sealing containers often use single-piece seals made from foamed or non-foamed supports, such as polypropylene (PP), polyethylene (PE), or polyethylene terephthalate (PET) seals. In some cases, double-piece seals including a cover and a support are used. These seals are designed to keep out oxygen, aromas, and moisture, but typically require adhesives or heat-sealing with metallic layers to achieve an airtight closure. Unfortunately, the use of thick metallic layers complicates recycling, as these must be separated from other components, increasing both costs and environmental impact. Additionally, even adhesives approved for food contact can raise regulatory concerns and may not be future proof as standards evolve.

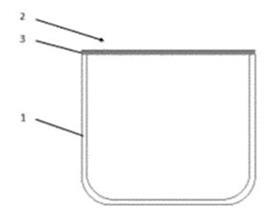

European Patent EP4414289, granted to Selig France in October 2025, describes a two-part seal for containers, making use of the natural properties of casein (a milk-derived protein), to overcome these challenges. The invention focuses on a lid (2) comprising an extruded film (3) made from casein and/or caseinate, which is designed to be in direct contact with the rim of a container (1), such as a jar. This film can be sealed at room temperature simply by moistening the contact area with water, eliminating the need for adhesives or heat-sealing metals.

This sealing solution ensures that the lid is biodegradable and recyclable, as well as the container and cap, streamlining waste processing and supporting circular economy goals. The absence of thick metallic layers further simplifies recycling.

The patented casein-based lid offers food manufacturers a way to future-proof their packaging against tightening regulations and meet consumer demand for eco-friendly solutions. By substituting adhesives and metals with a natural, biodegradable protein, companies can reduce their environmental footprint and potentially lower costs associated with recycling and compliance. Even in a well-established field of packaging innovation, such as food containers,

this patented technology demonstrates that new solutions can still deliver a competitive edge. The technology not only enhances sustainability but also maintains the high standards of product integrity required in the food industry. With patent protection, Selig France has secured commercial exclusivity for its innovation for a period of 20 years, positioning itself as a leader in next-generation packaging solutions.

No comments yet