OAL Connected is offering a solution to read newly introduced data embedded barcodes inline. Tesco has recently unveiled these data embedded barcodes on meat products in its Jack’s stores, with an anticipated roll-out to further products and sites, in a bid to reduce food waste.

OAL Connected’s label and date code verification solution is the only system currently on the market that can read the information contained within the barcode inline via existing scanners, protecting the packaging line from errors, emergency product withdrawals and product recalls.

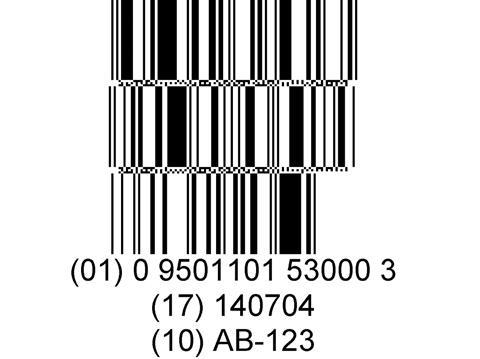

A data embedded barcode is an extended 1D barcode that can store more information, such as the global trade item number, expiration or best before date and batch number, in addition to other attributes used at the point-of-sale e.g. weight. These data embedded codes can be ‘stacked omnidirectional’ with just two barcodes stacked, or ‘expanded stacked’, with three or more on packaging. However, the widespread introduction of these barcodes may pose a challenge to manufacturers, not only in printing them but also because traditional label and date code verification solutions cannot read them, which opens manufacturers up to the possibility of incorrectly labelled products entering the supply chain, risking consumer health, the manufacturer’s reputation and its bottom line.

While ANSI grade verifying solutions can indicate the quality of the barcode and can read the information contained within, they cannot check that the details are correct before products leave the factory floor. Due to the importance of the information, this exposes manufacturers to a huge risk as there is potential for a product withdrawal and associated fine if the products supplied cannot be scanned at the till or contain the wrong information, and in the new format, there is not even the possibility for cashiers to input the data manually to reduce the risk.

What’s more, as manufacturers will now need to print the barcodes in-house, with their own staff programming the printers, the room for error is significant. As OAL Connected’s label and date code verification solutions are entirely independent of the printer, this ensures a full and thorough check of the information within the barcode before it leaves the packaging line to reduce the risk of incorrect labels being released into the supply chain.

OAL Connected understands that this capability has not been incorporated into traditional inline scanners and therefore, although reading may be possible with other solutions going forward, OAL Connected has already invested significant time in developing a solution to this challenge to ensure that manufacturers can deal with the new data embedded barcodes from day one.

Wayne Johnson, OAL Connected Director, comments, “Jack’s meat products are already carrying the data embedded barcode in store, and from our discussions with manufacturers, the roll-out to further products and stores is likely to take place in the near future. It’s vital for manufacturers to consider their current label & date code checks and whether they are able to cope with the potential challenge posed by Tesco’s forward-thinking update.”

FareShare’s food director, Mark Varney, claimed in 2016 that the food manufacturing industry is responsible for 4m tonnes of the 15m tonnes of food wasted in the UK every year, a revelation which led to the Courtauld 2025 commitment, coordinated by the Waste & Resources Action Programme (WRAP) (part of the Department for Environment, Food & Rural Affairs) to cut waste in the food chain by 20 per cent by 2025. The added information contained within data embedded barcodes offers retailers and manufacturers greater oversight at every point in the supply chain, particularly at the point of sale, contributing to the industry goal of dramatically reducing this figure. For suppliers, it helps to facilitate ordering and forecasting, better management of raw materials and offers greater insight on varieties and sources of origin, while retailers benefit from better waste management, targeted replenishment and rotation and targeted stock record counts thanks to the live view of products in stock.

Thanks to OAL Connected’s foresight, based on industry trends and discussions with existing customers, OAL understood that the introduction of data embedded barcodes was a likely change to the retailer landscape and so began developing a solution to read these data codes inline in late 2018. Existing OAL Connected customers simply need a software upgrade to existing scanners to be able to take advantage of this new capability and meet the retailer code of compliance.