SeaCube seeks to reduce emissions in refrigerated transport via reefer leases – powered by Greensee’s AI-driven CO2 emissions reporting technology – and battery-powered container gensets tested alongside Thermo King and CMA CGM.

Apparently, reefers – short for refrigerated containers – constitute around 10% of a ship’s container capacity while consuming between 20% and 30% of a vessel’s total power output. This is feared to contribute ‘significantly’ to CO2 emissions.

In response, SeaCube’s Green Reefer Leases aim to provide advanced energy analytics and optimized asset designs. They claim to unlock energy savings and emissions reductions of up to 20%, thus improving both cost and environmental performance.

The refrigerated containers come equipped with next-generation controllers, enhanced telematics, and efficient compressors, the company explains. Customers can consult real-time data analytics to help optimize their refrigeration operations, with variables like ambient temperature, cargo type, and tradeline all accounted for.

Furthermore, SeaCube’s Net-Zero Reefer Leases give customers the option to offset any remaining transport-related carbon emissions. Through this method, companies can buy carbon credits that contribute towards broader environmental initiatives like reforestation.

“Greensee’s advanced analytics empower customers to accurately monitor and report emissions, ensuring compliance while enabling real-time optimization of refrigerated transport,” said Luc Terrel, founder and CEO of Greensee. “Our partnership with SeaCube is a pivotal step toward a more sustainable future in cold chain logistics.”

Currently, SeaCube and Greensee are sponsoring a greenhouse gas reporting and reefer fleet organization pilot for Pacific International Lines (PIL). The initiative sets baseline metrics for decarbonization, and simultaneously identifies fuel saving and operational efficiency opportunities.

“Effective GHG reporting for refrigerated transportation contributes to providing PIL with good visibility on our emissions, helps us meet regulatory requirements, and supports our long-term goal of achieving net zero GHG emissions by 2050,” said Lim Chee Wei, general manager, Logistics Division at PIL.

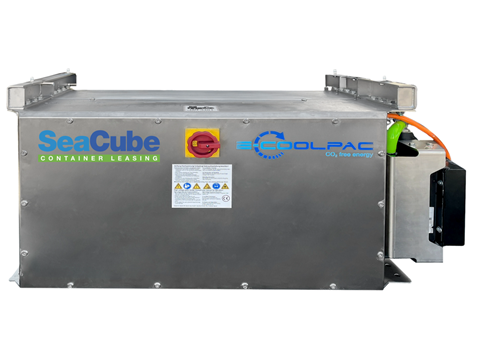

In a simultaneous development, SeaCube, Trane Technologies brand Thermo King, and CMA CGM are testing what is described as one of the first battery-powered refrigerated container gensets in the U.S. – Thermo King’s E-COOLPAC electric genset.

Designed to serve as a ‘zero direct emission’ solution, this battery power technology intends to transition last-mile refrigerated transport – minus truck power – into electricity. It claims to completely eliminate CO2 emissions and particulate emissions during operation, with its compatibility with renewable energy charging said to lower its carbon footprint further.

Various battery modules are available, as are extension packs to deliver between 35kWh and 105kWh’s worth of power. These can be fitted and retrofitted to marine container chassis in place of traditional diesel genset.

E-COOLPAC is compatible with such marine refrigeration units as CFF and Magnum Plus, alongside other brands of ISO1496-2 reefer units.

“Providing electric solutions for refrigerated transportation is part of Thermo King’s and Trane Technologies’ overall approach to reducing carbon emissions,” commented Claudio Zanframundo, president Thermo King EMEA Truck, Trailer, Bus and Global Marine, Rail and Air. “E-COOLPAC is a diesel genset alternative power source for reefers when they are not connected to grid or vessel power.

“It allows for lower emissions and adherence to local regulations when transporting refrigerated marine containers from ports to distribution centers, or those involved in daily reefer container transport.”

“This e-genset is a game-changer for our operations,” added Fabien Gresy-Aveline, vice president, Container Fleet, CMA CGM. “By transitioning away from diesel, we are taking a significant step toward more sustainable refrigerated transport.”

Gregory Tuthill, chief commercial officer at SeaCube Containers, concluded: “As a global leader in refrigerated intermodal equipment leasing, SeaCube is dedicated to investing in transformative sustainability solutions. These initiatives not only help customers meet their rigorous sustainability targets but also significantly reduce the carbon footprint of refrigerated transport.

“SeaCube and Greensee are setting the standard for sustainability in the cold chain industry. Through innovative solutions like energy analytics, the electric genset, and the Net-Zero Reefer Lease Program, we are providing practical, impactful pathways to help customers reduce emissions and achieve carbon neutrality.”

In similar news, IMA Life, MIRAI Intex, and ACT previously unveiled KryoAir, an air-based refrigeration system for freeze dryers intended to improve efficiency and ensure consistent cooling output. This reportedly avoids the use of high-GWP gases and ensures consistent cooling output for freeze-drying applications.

Groenlandia Tech and Inokor have also joined forces on Nuük, a temperature-controlled cooler for transporting hospital and pharmaceutical products or samples with real-time sample tracking and total access control.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet