Avery Dennison has launched three RFID-enabled In-Mold Labels (IMLs) to be embedded into reusable plastic packs during the injection moulding process, intended to facilitate accurate item-level scanning for greater visibility across operations.

Reportedly compatible with standard in-mould labelling equipment and materials, the labels contain RFID inlays designed to withstand the heat and pressure of injection moulding and maintain their performance across the manufacturing process.

As such, they are also believed to be suitable for repeated washing and handling cycles, therefore extending product lifespans. In doing so, they aim to lower waste while facilitating closed-loop reuse systems.

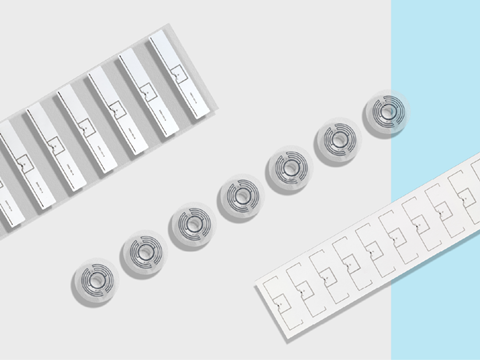

The new line comprises three solutions, including AD Anchor U9 IML (UHF). This variant is intended for general industry, supply chain, and logistics applications; it can track plastic assets such as pallets, plant trays, shipping bins, waste containers, and production and automotive components.

Meanwhile, the AD Line U9XE IML (UHF) is geared towards container tracking, waste management systems, and other industrial applications requiring thinner label construction.

Thirdly, AD Spiral U9 IML (UHF) is designed for reusable packaging used in hospitality, catering, events, and other consumer-facing sectors. Said to support washing durability, hygiene, and cycle counting, this solution is reportedly compliant with EU regulations on food contact, including Commission Regulation (EU) 10/2011 and Regulation (EC) 1935/2004.

Embedding RFID functionality within the labels is expected to lessen the possibility of human error in inventory handling. It also claims to unlock real-time visibility when moving items, as well as provide information on actual returns to facilitate more accurate invoicing.

Avery Dennison asserts that these features are useful in event services, closed-loop logistics, and other high-volume environments, with brands and operators able to streamline their operations, improve accountability, and take steps to align with sustainability and regulatory targets.

The label range is anticipated to improve track-and-trace capabilities and enhance efficiency, all while reducing the manual effort required to run a reusable packaging system.

“Our new IML portfolio reflects Avery Dennison’s commitment to enabling scalable reuse models and driving greater supply chain efficiency,” says Mathieu De Backer, vice president innovation & sustainability, Avery Dennison Smartrac. “By embedding RFID directly into moulded plastic items, we create an integrated solution that offers full visibility throughout each vessel’s lifecycle.

“This technology enables precise tracking of returnable transport items (RTIs) in industrial settings, and vessels in consumer applications. Additionally, with each product having a digital twin, we ensure transparent traceability across the supply chain, supporting compliance teams across multiple sectors.”

In another recent development, Avery Dennison teamed up with The Kroger Co. to implement RFID-embedded labels into the retail company’s bakery department. This item-level digital identification was hoped to keep inventory information up-to-date and accurate, ensuring that food stays fresh, fewer supplies are wasted, and associates spend less time taking stock of inventories.

Since then, Checkpoint Systems has designed an RFID inlay for microwaveable food packaging. Suitable for plastic, glass, and various other materials, it seeks to balance RFID functionality with food safety and durability, apparently maintaining 50% of its maximum read range after 45 microwave cycles.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2025

How are the top brands progressing on packaging sustainability?

Everything you need to know about global packaging sustainability regulation in 2025

The key to increasing the use of reusable packaging in supermarkets

No comments yet