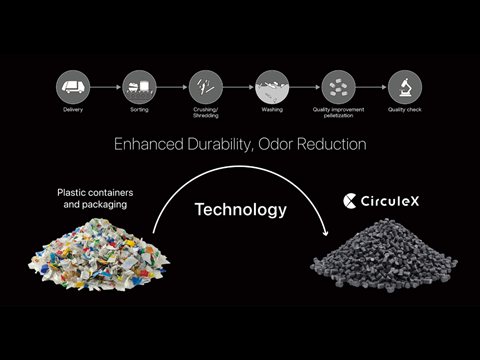

TBM has unveiled its CirculeX material, made from post-consumer recycled plastics – a solution believed to avoid poor strength and unpleasant odour while reducing CO2 emissions by up to 61%.

CirculeX is manufactured with TBM’s proprietary compounding and melt-kneading technology from its LIMEX business, sourcing its feedstock from plastic packaging and containers in the household recycling stream.

Reportedly, the solution cuts CO2 emissions by up to 6.43 kg per 1 kg. Next to virgin plastics, CirculeX is believed to be 29% more durable and 47% stronger when bent.

Furthermore, CirculeX is said to achieve a 126% increase in bending strength and a 76% increase in impact strength compared with conventional post-consumer recyclate. Improvements in the washing process are also thought to reduce odour by approximately 60% next to conventional PCR from plastic packaging.

The material is hoped to overcome high recyclate prices and supply constraints. TBM allows consumers to tailor the strength, odor grade, mechanical strength, and flowability of CirculeX to suit their own needs.

The company intends to mass-produce CirculeX at its Yokosuka Circular Factory earlier this year, with plans to expand the material beyond conventional post-consumer and post-industrial applications.

In other news, INEOS Olefins & Polymers Europe has revealed its new Recycl-IN hybrid polymer grade. Designed to contain 70% recycled material, the solution is set to improve strength, aesthetics, and processing ease in contact-sensitive cosmetics packaging.

Borealis and Borouge have also unveiled a global portfolio of mechanically recycled, post-industrial and consumer recyclates and compounds. The lineup is expected to help customers lower carbon footprints and meet ambitious sustainability targets.

If you liked this story, you might also enjoy:

The ‘complex reality’ of reusable packaging in Europe

Single-use packaging versus reusable packaging: Which is more sustainable?

The ultimate guide to global packaging sustainability regulation

No comments yet