From the first quarter of 2025, Mondi expects to lower nitrogen oxide emissions by up to 10%, greenhouse gas emissions by over 20%, and gas consumption by about 25% at its fine paper mills in Neusiedler, which have been upgraded under a €20 million investment.

The investment programme was funded by Mondi and supported by the European Union’s NextGenerationEU recovery plan.

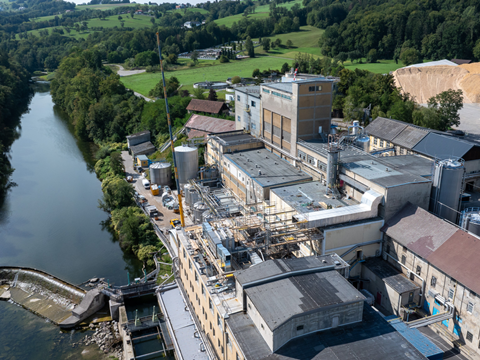

As part of the programme, Mondi plans to rebuild the facility’s recovery boiler and associated infrastructure. Doing so is set to boost its energy efficiency and improve its overall performance.

In order to tackle greenhouse gas emissions and help improve safety, the gas burners used for air heating in the pulp dryer will be replaced with steam heat exchangers. A steam accumulator will be installed to balance fluctuations in steam demand, which is set to enhance both turbine performance and efficiency.

A new rotor will be implemented into the steam turbine to increase electricity production, and a new steam system and heat recovery will be introduced for the paper machine. Mondi has also set its sights on improving customer reel output with wider optimization.

Meanwhile, upgrades to its Theresienthal site seek to make the steam and condensate system in the paper machine more efficient; ramp up automation in the additive kitchen; and introduce a refined winder concept.

“We are proud to invest in technology that drives efficiency, reduces emissions, improves product quality, and strengthens our resilience,” says Florian Döbl, managing director of Mondi Neusiedler. “These measures will reduce our greenhouse gas emissions by 20%, and we will consume around a quarter less gas in future, all contributing to our sustainability commitments.”

The news comes after the completion of a €95 million investment at Mondi’s its Świecie containerboard mill. Intended to increase kraftliner capacity by 55,000 tonnes and unlock more resource-efficient production, the investment included a rebuild of the facility’s PM2 and PM5 paper machines; a new anaerobic treatment plant with an integrated cooling system; and upgrades to the pulp mill, the recycled fibre line, and the energy recovery system.

In other news, DS Smith has invested €34.4 million into its Hungarian operations. By implementing new converting equipment and an updated corrugator, the company expects to boost its manufacturing capacities by 40%.

It has also invested over €25 million into its production lines and machinery parks in Kielce, Bełchatów, and Sosnowiec, which will fund the installation of new machinery – including a new die-cutter and paper bag technology – and improve automatization and precision in the flexography department. In the process, the company plans to increase its presence in the Polish marketplace.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet