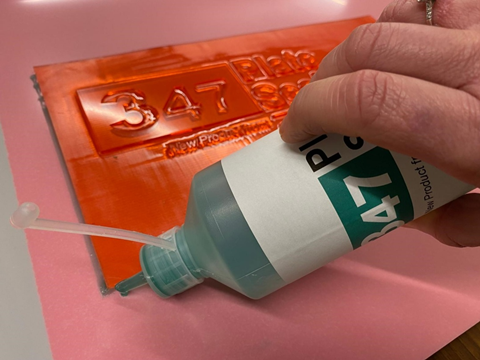

Corrugated and flexo printing solutions provider LeadEdge Flexo has launched its 347 Plate Sealer, developed to improve additional production efficiencies.

Forming a skin in 3 minutes and 47 seconds, the company says the 347 Plate Sealer has been formulated in response to customer feedback for a faster drying solution – compared to a drying time of 20-30 minutes with the previous version.

Apparently, it helps secure plates in place on the shim more rapidly, creating a protective barrier to prevent debris and fluids from disrupting the mounting process, and helps to reach the stage of hanging and stacking print stereos (printing plates) more quickly. As such, it is said to optimize production and gain efficiencies.

The company says print stereos are a specific area where there remains potential to make improvements in corrugated post-print manufacturing and increase the efficiency of the overall production environment.

LeadEdge Flexo sales director, Jon Moore, said: “Knowledge of the printing process is one of the pillars of our success and enables new-found levels of overall equipment effectiveness (OEE) to be realised by our customers. Plate sealers are a part of that and is an area where we can help make genuine gains. This new product is the solution for those frustrated by the slow drying times of plate sealers.”

In similar news, digital embellishment provider Scodix recently unveiled its first AI (artificial intelligence) tool - Scodix AI - ahead of drupa 2024, aiming to address growing demand for automation tools among print providers and designers. The company says its technology uses learnings from databases of Scodix-enhanced pages to automate the embellishment design process, analyzing designs before suggesting intelligent design choices.

Earlier this month, Fiery said it would be attending drupa 2024 with a range of printing technologies for packaging, direct-to-film, and industrial applications, as well as new DFE solutions and workflow software for digital print. Fiery’s specialty production printers utilize AI, cloud, and automation technologies in an effort to achieve high-quality colour, precision, efficiency, and profitability.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

The ultimate guide to global plastic sustainability regulation

No comments yet