Researchers at The University of Maine aim to streamline the commercial adoption of cellulose nanofibers as a packaging material by developing an electrostatic contact dewatering technique, thus speeding up the drying process.

Alongside starch, polylactic acid (PLA), and polybutylene adipate terephthalate (PBAT), cellulose nanofibers are often used to replace fossil-based plastics with biopolymer alternatives. Yet their high water content and high viscosity at low solids can prolong drying times.

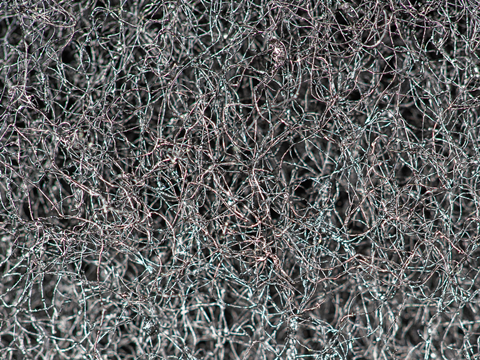

As such, Dr. Pradnya D. Rao, Dr. Carl Tripp, and Dr. Doug Bousfield at The University of Maine have developed an electrostatic contact dewatering process. It utilizes the electrostatic attraction between negatively charged cellulose nanofibers and cationic precipitated calcium carbonate particles – a process thought to reduce drying time by five times and improve the cost efficiency of cellulose nanofiber films.

Furthermore, a study published in the Cellulose journal suggests that the composite materials offer ‘superior’ strength, with the modulus of such films said to be over 50% higher than polypropylene equivalents. The researchers add that their solution could assist in the pursuit of more sustainable materials that do not compromise costs.

It is now thought that high solid slurries of cellulose nanofibers can be produced more efficiently. Various industries are now expected to incorporate them into their applications, including coatings, food packaging, biomedical devices, cosmetics, and electronics.

Nanocellulose is a renewable material and is therefore expected to offer ‘limitless potential’ in the pursuit of more environmentally friendly materials. The researchers underline that further developments in nanocellulose applications will be published in the future.

In a previous edition of the Packaging Europe podcast, our editor at large, Elisabeth Skoda, spoke to Kati Ekman, Tuomas Puonti, and Mateo Saavedra del Oso from Stora Enso Packaging Materials about microfibrillated cellulose (MFC) – specifically its role in lightweighting paperboard and supporting the efficient use of fibres.

Releaf Paper also introduced a self-assembled box and wrapping paper to its product lineup back in January. The company extracts cellulose from the fibres of fallen leaves and incorporates them into packaging that aims to combine visual appeal, functionality, and sustainability into a single pack.

If you liked this story, you might also enjoy:

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Reuse vs. single use – which is better for the environment?

The ultimate guide to global plastic sustainability regulation

No comments yet