Researchers from the University of Birmingham have designed a new type of photocurable resin made entirely from bio-sourced materials, which can be 3D printed, recycled, and then printed again.

Current 3D printing often relies on epoxies or acrylics, which come mostly from petrochemical feedstock, whereas this new resin is made from lipoic acid, a naturally occurring fatty acid molecule that is 100% bio-based, and commonly sold as a dietary supplement.

The recyclability of conventional resins remains limited, due to them needing to offer irreversible bonds when cured and hardened.

Contrastingly, this new rein solution can be printed then broken down into its constituent parts, recycled, and reprinted. This would be a fully closed-loop system if it wasn’t for the small amount of photoinitiatior which is added to maintain the material’s curable properties.

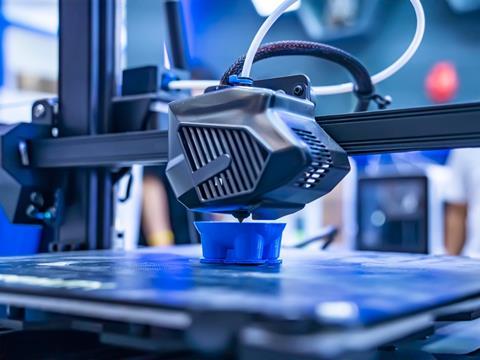

The new resin is compatible with light-initiated printing techniques such as DLP, SLA or by direct ink write, or InkJet printing, and provides high fidelity, with resolution down to 0.05mm.

The research team, led by Professor Andrew Dove from Birmingham’s School of Chemistry, says that the resin can complete two ‘recycles’, and anticipates further recycling is possible, meaning the material could be used for packaging.

University of Birmingham Enterprise has filed a patent application covering the composition of the resin, and its use in 3D printing, and is now seeking licensing and co-development partners.

If you liked this story, you might also enjoy:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation

No comments yet