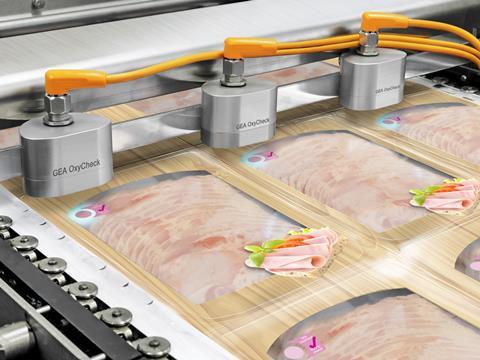

The highlight of GEA's interpack stand was its next generation quality control solution - the GEA OxyCheck, the world’s first in-line measurement system that checks the oxygen content and seal integrity of every single food product packaged in modified atmosphere.

The innovative benefit of OxyCheck is that each Modified Atmosphere Packaging unit is non-invasively inspected after sealing on a GEA thermoformer, rather than needing to be damaged by a needle as was general practice up until this point. This makes costly spot checks obsolete, while films and seals remain intact and there is no loss of product or materials. As a member of the “SAVE FOOD” initiative, this is GEA’s contribution to reducing food waste during production.

Manufacturers, retailers and consumers all benefit

In large part, GEA decided to develop the GEA OxyCheck measurement system to meet the needs of discriminating consumers who attach ever greater importance to having safe and freshly packaged foods. “For us, what consumers want is just as important as what retailers want, which is products with a longer shelf life. Both have a bearing on which hygiene and quality requirements must be met, which in turn is what manufacturers must fulfil,” Volker Sassmannshausen, Senior Product Manager at GEA, said. “All three target groups benefit from GEA OxyCheck, because the system helps to ensure that food reaches consumers in perfect condition.”

Adding value to MAP

Today more than half of all retail fresh food – meat, fish, poultry, fruits and vegetables, confectionery and baked goods as well as dairy products – is packaged in a modified atmosphere. During this process, a gas mixture of carbon dioxide and nitrogen is injected into a package prior to sealing. This slows down decay, thus extending the shelf life of the packaged product. A small percentage of oxygen remains in the package by virtue of the process, but this may not exceed a threshold to avoid early spoilage of the goods. GEA OxyCheck carries out the important task of monitoring the residual oxygen content directly during production on the GEA PowerPak thermoformer.

Sensor spot on the inside of the film provides information about oxygen content

The GEA technology uses a sensor spot made of a polystyrene-based fluorescent dye that is printed on the inside of the film. Similar to an indicator strip, the wavelength of the dye changes depending upon the oxygen content inside the package. Sensors on the GEA PowerPak thermoformer activate this sensor spot and then take a reading. GEA has developed a special method for calculating the oxygen concentration based on the light emitted and the temperature. The new measurement system has no effect on either the line speed or the throughput of the GEA PowerPak.

No waste of food or packaging materials

Up until now, spot checks have been carried out to measure the oxygen content in MAP – which means that less than 0.5 percent of the packs manufactured are typically tested. Spot checks involve the removal of packs from the line and their inspection through an invasive probe. When a pack does not meet specifications, the line is halted and all packs preceding it up to the last pass are destroyed. However, even perfectly fine packages are disposed of because they are damaged by the needles during the testing process. In contrast, the GEA OxyCheck process is completely non-invasive and neither the product nor the packaging materials go to waste. And 100 percent of the manufactured packs are inspected as well. In the end, only packages that meet all specifications enter the supply chain. Sassmannshausen added, “We also help food manufacturers avoid costly recalls of whole batches, which retailers can demand even if only one pack shows early spoilage.”

Safe outcome, safe technology

GEA OxyCheck has been approved by the U.S. Food and Drug Administration (U.S. FDA) and meets all relevant EU regulations for Food Contact Materials (FCMs). The liquid is similar to the materials used in making the packaging films. The sensors work with the pulsed light of an LED, which is safe for both products and operators. The process has no effect on either the composition of the modified atmosphere or the package content. Initially designed for use on the horizontal thermoformers of the PowerPak line, GEA OxyCheck will also be available as an optional feature or retro-fit upgrade for other equipment with MAP capabilities. In the future, GEA is planning to offer the system for other applications such as the vertical thermoformer as well.

“SAVE FOOD” – SAFE FOOD through GEA OxyCheck

GEA has been a member of “SAVE FOOD” since 2013, the initiative that is fighting to eliminate food waste. To meet the challenge of securing the food supply for a growing global population, members are working to reduce food loss along the value chain. After all, even today, approximately one third of the food produced – 1.3 billion tons a year – still goes to waste for a variety of reasons.

One focus of the initiative is on packaging that is designed and applied to be both safe and conserve resources. And this is where the Düsseldorf-based technology group GEA, one of the TOP suppliers of the food processing sector, comes in: without “safe food” it is not possible to “SAVE FOOD”. “We believe that we can only counteract the undesirable developments of the past years through maximum product safety,” Sassmannshausen said to explain why GEA joined the initiative. “This is why, through our technological advances, we are making it possible for the industry to safely manufacture food products and avoid waste beginning in production. With GEA OxyCheck, we are doing our part to fight against food waste.”