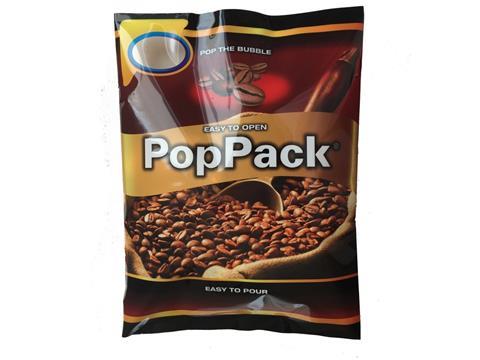

PopPack’s patented EasyPop solution allows flexible and semi-rigid packaging to be opened with the pop of an air bubble incorporated into its design. Replacing difficult-to-open seals, the air bubble draws on familiar sensory experiences to guide consumer engagement and provide tamper protection. This small and intuitive addition can boost the accessibility of a range of familiar primary packaging types – showing that a simple innovation can make a big difference for consumers.

We spoke to Cheryl Harrison from PopPack to learn more about the EasyPop solution and the company’s packaging insights.

An experience that is both familiar and new

“In its basic form, the package is interactive and memorable,” says Cheryl Harrison, director of PopPack. The popping of the air bubble, she adds, “offers an experience of all the senses of sight, sound, tactile touch and feel”.

For example, Harrison highlights the “memorable sound” that EasyPop air bubbles make when popped by the consumer. This draws on the familiarity of packaging that consumers will have encountered before, such as bubble wrap, which also creates a distinctive and popular popping sound.

“For consumers, opening the packaging is intuitive and interactive,” Harrison explains. The look and feel of the bubble invites consumers to engage with the packaging, then creates a sensory reward with the ‘pop’ that follows.

What’s new about EasyPop is that it is part of the primary packaging, while bubble wrap and other air-based solutions often comprise the secondary and tertiary packaging in which a product might be stored or transported.

“The ideal uses are for liquids, flowable products and solid goods, both food and non-food, such as consumer goods products,” Harrison notes of EasyPop’s applications. Flexible packaging in these segments, like pouches, often features flat seals or a variety of cap types that consumers are more accustomed to.

But this hasn’t impacted the outlook for EasyPop. According to Harrison, “customers who are brand owners, converters, and packaging machinery companies are searching for new solutions which offer […] novelty”. The EasyPop solution therefore takes a familiar look, feel, and sound, and integrates this into the primary package to provide a unique opening experience.

Not just hot air when it comes to accessibility

The EasyPop mechanism, Harrison emphasises, is designed to be “accessible for all ages and abilities”.

By removing the need for ripping, cutting, or tearing the package – which might involve sharp instruments or even biting – EasyPop allows flexible packaging for applications like food and beverages to be opened by children where appropriate. This offers autonomy and thus engagement across age groups, and can complement branding aimed specifically at children.

In addition, EasyPop enables packaging to be opened one-handed and often in a single action, which can benefit elderly and disabled consumers. For example, the stiffness and pain associated with arthritis can make it difficult to open packaging that requires tearing or the use of scissors, which is eliminated with the EasyPop solution. In addition, the “tactile” and “intuitive” nature of EasyPop could aid blind or partially sighted people with opening as the bubble is sensorily distinct from the rest of the packaging.

Harrison says that the EasyPop solution is “consumer-centric”, and accessibility is a key but too often overlooked aspect of this. When discussing the future of EasyPop, Harrison adds, “we will continue to work on creating positive human experiences that include greater convenience, social value and personal interactions with packaging.”

Easy to open – but not easy to tamper

Of course, some packaging is deliberately difficult to open, especially for segments such as pharmaceuticals where products can be dangerous if used incorrectly or sensitive to environmental conditions.

While EasyPop is not necessarily suitable for all applications, Harrison emphasises that it does not compromise on security for its customers. In fact, the distinctive ‘pop’ of EasyPop’s air bubble is not just about the sensory experience – it “re-assures the consumer that the package is fresh and tamper evident”.

Again, this draws on familiar experiences for consumers. The popper button often found on the lids of food containers like jars, for example, similarly relies on touch and sound to demonstrate the integrity of the product.

Therefore, the ‘pop’ of EasyPop’s air bubble is an experience reserved for its end-use consumer only, for both enjoyment and security purposes. “First and foremost, our EasyPop packages are designed to enhance and delight the customer experience,” says Harrison; security is a subtle but significant part of this.

“EasyPop is also designed to be interoperable with smart devices, and sensors used to relay real-time supply chain information,” Harrison tells us.

EasyPop can work with smart packaging that incorporates technology like NFC and tokenisation, providing traceability solutions to its customers. The benefits of this, according to Harrison, include “bringing interactivity [and] product information on demand” to companies that use EasyPop.

Sealing the deal on sustainability

“With our packaging industry specialists and customers,” Harrison explains, “our goal is to accelerate and scale sustainable packaging solutions for the industry which are cost-effective and efficient, while reducing supply chain waste and encouraging improved recycling processes.”

EasyPop eliminates the need for tear strips, which are often placed in the incorrect disposal stream, and reduces material waste and weight as packages no longer require caps. The air bubble system can also be configured to allow resealing, so packaging can be reused, and the freshness of food and beverages can be maintained for a longer period.

This will be especially important in some markets. For example, Harrison identifies EU legislation that requires bottle caps to be tethered to the bottle, an issue completely eradicated by EasyPop as “there is no cap and no fitment, so there is nothing to tether or to become litter in the environment.”

In addition, Harrison claims that EasyPop is “more easily collected and sorted” than sealing alternatives as it is made from a monomaterial film that is “suitable for reuse and upcycling”.

“As company founders and innovators, we care deeply about the stewardship of our environment and preservation of the natural resources of our world. It is our hope that packaging will be valued as part of a connected circular system.”

What’s next?

“EasyPop is diligently working with European partners to produce machinery and films to maximize throughput for packaging production lines,” Harrison informs us.

Going forward, the company is focused on scaling and streamlining production lines that integrate EasyPop, which are already operating in the Netherlands, Germany, Belgium, and Sweden, among others. The EasyPop portfolio can be cost-effectively integrated into existing vertical form, fill and seal (VFFS), horizontal FFS, and thermoform packaging lines, according to PopPack’s website.

Sustainability, while already a focus, is a future priority for PopPack. Harrison concludes: “It is our sincere hope to enable a future value chain with packaging solutions that greatly reduce harmful environmental impacts and eliminate plastic waste from packaging found in our world’s lands, rivers, and oceans.”