Transport packaging is a cornerstone of global trade: Without boxes, pallets or corrugated board, freight transport would come to a standstill. Export packaging ensures safe, fast handling of goods of all sizes delivered to destinations all over the world.

As well as protecting the goods, the packaging has to meet the needs of the various participants in the supply chain: Freight forwarders, logistics companies, shippers and customers expect handling to be simple and cost-efficient. One of the ways in which the manufacturers of transport packaging meet these requirements is by offering standardised products such as wooden boxes for light or heavy loads, single or double pallets, crates, corrugated cardboard sheets and boxes, bubble wrap and industrial shrink film, polyethylene film and aluminium foil. Suppliers of a wide range of export packaging will be presenting their solutions at FachPack in September 2018.

Getting ready for the digital transformationThe Association of Corrugated Board Manufacturers (VDW) reports that two-thirds of all transport packaging is made from corrugated cardboard. This kind of export packaging is inexpensive and light, but it is also strong and reliably cushions impacts. For heavy goods, heavy-duty corrugated board can be used to protect the products during land, air or sea transport. Other advantages of this type of packaging are its suitability for storage and ease of recycling.

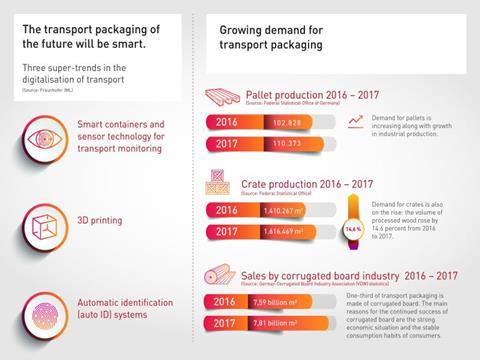

The corrugated board sector is also getting ready for the digital transformation: In 2017, the VDW carried out a survey in conjunction with the Fraunhofer Institute for Material Flow and Logistics (IML). It found that in future, transport packaging will not just carry information but will actually generate information itself. The packaging as such will share data at various points in the supply chain and constantly monitor its contents.

These automatic ID systems include RFID technology, for example. The data obtained can be used to further improve the supply chain. “In future there will be a demand for sensors that provide information about the nature and impact of any transportation stresses,” explains Christiane Auffermann, expert on commercial logistics at the Fraunholfer IML Institute who was in charge of the survey. Experts also expect that 3D printing will make it possible in future to customise packaging to produce strong packaging with less material. As part of the supporting programme at FachPack, companies and institutes will once again explore and enlarge upon the latest trends in transport packaging. In this context, brief presentations, discussions and special shows will provide new inspiration for the use of different packing materials and technologies (www.fachpack.de/programme).

More in demand than everAs well as corrugated board, wood in the form of standard pallets and wooden boxes is commonly used for export packaging, providing two essential means of transport for global logistics. Adapted to standardised sea containers, most items begin their journey to the customer on this kind of pallet. The demand for pallets and wooden boxes is matching the growth in production and export activity. “Overall, the significant rise in production volumes reflects the good economic climate, which has led to greater demand for wooden load carriers and packaging in Germany and increasingly, in other countries,” says Marcus Kirschner, Managing Director of the German Association of Wood Packaging, Pallets and Export Packaging (HPE).

New approaches to automation and traceabilityThe digital transformation offers great potential for commercial logistics. Suppliers of pallets are currently looking into the technical possibilities of the blockchain, a distributed database technology in which data cannot be modified, directly retrieved or deleted. Originally devised for cryptocurrency transactions, the technology is increasingly being tested for production processes and in logistics.

In the meanwhile, the industry organisation for standardisation GS1 is conducting a pilot project with companies from trade, industry, logistics, IT and the research field to investigate to what extent this technology can facilitate paperless load carrier management. According to GS1, a successful implementation of this technology would be a quantum leap for the sector. Today, the pallet note is still part of the daily routine of every truck driver. The new technology could offer lots of new options for automating processes and ensuring traceability.