In this edition of our Innovation Spotlight series, Echo Machinery introduces the MRZK-200P – a new vacuum packaging machine that the company says can improve efficiency while improving hygiene and safety.

Echo Machinery is the largest manufacturer of premade pouch packaging machines in China. Among our solutions, rotary vacuum packaging products have always been in a leading position.

Based on 20 years of experience and hundreds of iterations of updates, we are launching our Vacuum Flatten Packaging Machine MRZK-200P in China. The machine works at speeds of up to 50 Bags/Min, opening new possibilities for the vacuum packaging industry.

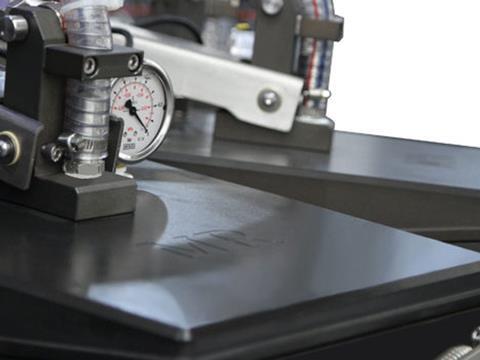

Based on our original rotary vacuum packaging machine, we lay the vacuum chamber horizontally to keep the material flat during the vacuum process and obtain an unprecedented packaging experience.

Our new machine replaces manual operation, improves efficiency, and reduces material hygiene and safety risks. We insist on innovation in packaging, considering the needs of customers and consumers.

We abandoned the traditional way of pressing the material by hand – the fully automated process runs through the entire production line to reduce the contact between people and materials on the production line. We do not destroy the original form of the material while discharging the air in the packaging.

A piece of good vacuum packaging should be as close as possible to perfection in every detail. Not only the main part where the material is located, but the sealing treatment should also be strictly controlled. A clean seal is a basic requirement and a guarantee of good vacuum packaging.

After multiple reshapings, the material packaging effect reaches a high standard. Sealing in the vacuum chamber ensures sanitation, safety, and the pack’s vacuum tightness. MRZK-200P has carried out stringent treatment on the packaging seal to ensure that it is clean and free of impurity.

Sealings treated by other semi-automatic vacuum equipment in the past always carried more sundries and defects. For example, it isn’t uncommon for the seal folding to contain oil and other materials – leading to air leaks and increasing the risk of loss.

MRZK-200P can be smoothed and shaped in one machine, and the finished packaging products are of high quality, which brings new surprises and a better experience to consumers.

For more information go to: https://www.echomachinery.com/packaging-machines/vacuum-flatten-packaging-machine/

Or email echomachinery@echomachinery.com

This content was sponsored by Echo Machinery.